Page 195 - Electromechanical Devices and Components Illustrated Sourcebook

P. 195

Chapter 9 Connectors 157

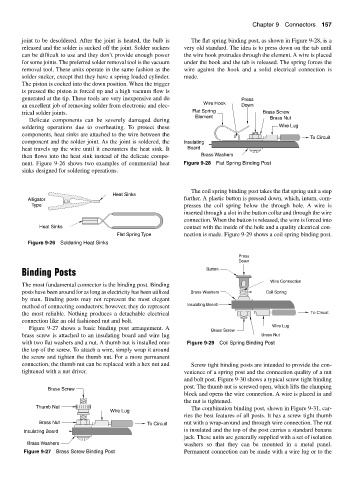

joint to be desoldered. After the joint is heated, the bulb is The flat spring binding post, as shown in Figure 9-28, is a

released and the solder is sucked off the joint. Solder suckers very old standard. The idea is to press down on the tab until

can be difficult to use and they don’t provide enough power the wire hook protrudes through the element. A wire is placed

for some joints. The preferred solder removal tool is the vacuum under the hook and the tab is released. The spring forces the

removal tool. These units operate in the same fashion as the wire against the hook and a solid electrical connection is

solder sucker, except that they have a spring loaded cylinder. made.

The piston is cocked into the down position. When the trigger

is pressed the piston is forced up and a high vacuum flow is

generated at the tip. These tools are very inexpensive and do Press

an excellent job of removing solder from electronic and elec- Wire Hook Down

trical solder joints. Flat Spring Brass Screw

Element Brass Nut

Delicate components can be severely damaged during

soldering operations due to overheating. To protect these Wire Lug

components, heat sinks are attached to the wire between the

To Circuit

component and the solder joint. As the joint is soldered, the Insulating

heat travels up the wire until it encounters the heat sink. It Board

then flows into the heat sink instead of the delicate compo- Brass Washers

nent. Figure 9-26 shows two examples of commercial heat Figure 9-28 Flat Spring Binding Post

sinks designed for soldering operations.

The coil spring binding post takes the flat spring unit a step

Heat Sinks

Alligator further. A plastic button is pressed down, which, inturn, com-

Type presses the coil spring below the through hole. A wire is

inserted through a slot in the button collar and through the wire

connection. When the button is released, the wire is forced into

Heat Sinks contact with the inside of the hole and a quality electrical con-

Flat Spring Type nection is made. Figure 9-29 shows a coil spring binding post.

Figure 9-26 Soldering Heat Sinks

Press

Down

Binding Posts Button

Wire Connection

The most fundamental connector is the binding post. Binding

posts have been around for as long as electricity has been utilized Brass Washers Coil Spring

by man. Binding posts may not represent the most elegant

method of connecting conductors; however, they do represent Insulating Board

the most reliable. Nothing produces a detachable electrical To Circuit

connection like an old fashioned nut and bolt.

Wire Lug

Figure 9-27 shows a basic binding post arrangement. A

Brass Screw

brass screw is attached to an insulating board and wire lug Brass Nut

with two flat washers and a nut. A thumb nut is installed onto Figure 9-29 Coil Spring Binding Post

the top of the screw. To attach a wire, simply wrap it around

the screw and tighten the thumb nut. For a more permanent

connection, the thumb nut can be replaced with a hex nut and Screw tight binding posts are intended to provide the con-

tightened with a nut driver. venience of a spring post and the connection quality of a nut

and bolt post. Figure 9-30 shows a typical screw tight binding

post. The thumb nut is screwed open, which lifts the clamping

Brass Screw

block and opens the wire connection. A wire is placed in and

the nut is tightened.

Thumb Nut The combination binding post, shown in Figure 9-31, car-

Wire Lug

ries the best features of all posts. It has a screw tight thumb

Brass Nut To Circuit nut with a wrap-around and through wire connection. The nut

Insulating Board is insulated and the top of the post carries a standard banana

jack. These units are generally supplied with a set of isolation

Brass Washers washers so that they can be mounted in a metal panel.

Figure 9-27 Brass Screw Binding Post Permanent connection can be made with a wire lug or to the