Page 194 - Electromechanical Devices and Components Illustrated Sourcebook

P. 194

156 Electromechanical Devices & Components Illustrated Sourcebook

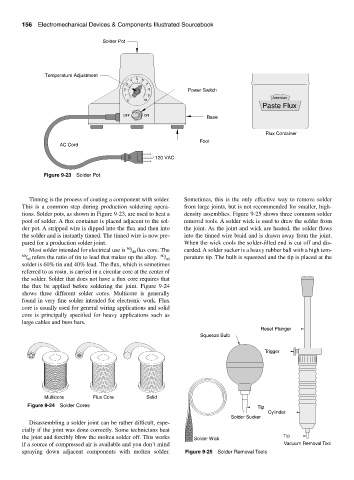

Solder Pot

Temperature Adjustment

5

4 6

3 7

2 8 Power Switch

1 9

American

0 10

Paste Flux

OFF ON

Base

Flux Container

Foot

AC Cord

120 VAC

Figure 9-23 Solder Pot

Tinning is the process of coating a component with solder. Sometimes, this is the only effective way to remove solder

This is a common step during production soldering opera- from large joints, but is not recommended for smaller, high-

tions. Solder pots, as shown in Figure 9-23, are used to heat a density assemblies. Figure 9-25 shows three common solder

pool of solder. A flux container is placed adjacent to the sol- removal tools. A solder wick is used to draw the solder from

der pot. A stripped wire is dipped into the flux and then into the joint. As the joint and wick are heated, the solder flows

the solder and is instantly tinned. The tinned wire is now pre- into the tinned wire braid and is drawn away from the joint.

pared for a production solder joint. When the wick cools the solder-filled end is cut off and dis-

60

Most solder intended for electrical use is / flux core. The carded. A solder sucker is a heavy rubber ball with a high tem-

40

60 / refers the ratio of tin to lead that makes up the alloy. / 40 perature tip. The bulb is squeezed and the tip is placed at the

60

40

solder is 60% tin and 40% lead. The flux, which is sometimes

referred to as rosin, is carried in a circular core at the center of

the solder. Solder that does not have a flux core requires that

the flux be applied before soldering the joint. Figure 9-24

shows three different solder cores. Multicore is generally

found in very fine solder intended for electronic work. Flux

core is usually used for general wiring applications and solid

core is principally specified for heavy applications such as

large cables and buss bars.

Reset Plunger

Squeeze Bulb

Trigger

Multicore Flux Core Solid

Figure 9-24 Solder Cores Tip

Cylinder

Solder Sucker

Disassembling a solder joint can be rather difficult, espe-

cially if the joint was done correctly. Some technicians heat

the joint and forcibly blow the molten solder off. This works Solder Wick Tip

if a source of compressed air is available and you don’t mind Vacuum Removal Tool

spraying down adjacent components with molten solder. Figure 9-25 Solder Removal Tools