Page 228 - Electromechanical Devices and Components Illustrated Sourcebook

P. 228

190 Electromechanical Devices & Components Illustrated Sourcebook

Component

Mounting Holes

ON

Die Cast Box

Gasket Ridge

OFF

Cover Mounting

Holes

Receptacle Switch

Plate Plate

NPT Ports

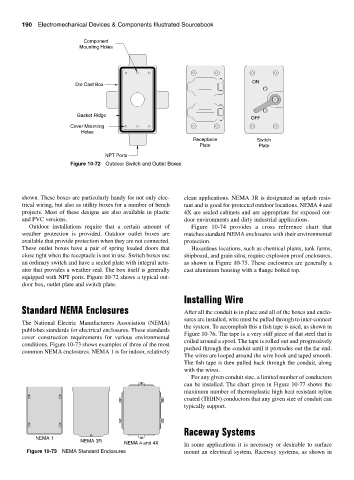

Figure 10-72 Outdoor Switch and Outlet Boxes

shown. These boxes are particularly handy for not only elec- clean applications. NEMA 3R is designated as splash resis-

trical wiring, but also as utility boxes for a number of bench tant and is good for protected outdoor locations. NEMA 4 and

projects. Most of these designs are also available in plastic 4X are sealed cabinets and are appropriate for exposed out-

and PVC versions. door environments and dirty industrial applications.

Outdoor installations require that a certain amount of Figure 10-74 provides a cross reference chart that

weather protection is provided. Outdoor outlet boxes are matches standard NEMA enclosures with their environmental

available that provide protection when they are not connected. protection.

These outlet boxes have a pair of spring loaded doors that Hazardous locations, such as chemical plants, tank farms,

close tight when the receptacle is not in use. Switch boxes use shipboard, and grain silos, require explosion proof enclosures,

an ordinary switch and have a sealed plate with integral actu- as shown in Figure 10-75. These enclosures are generally a

ator that provides a weather seal. The box itself is generally cast aluminum housing with a flange bolted top.

equipped with NPT ports. Figure 10-72 shows a typical out-

door box, outlet plate and switch plate.

Installing Wire

Standard NEMA Enclosures After all the conduit is in place and all of the boxes and enclo-

sures are installed, wire must be pulled through to inter-connect

The National Electric Manufacturers Association (NEMA)

the system. To accomplish this a fish tape is used, as shown in

publishes standards for electrical enclosures. These standards

Figure 10-76. The tape is a very stiff piece of flat steel that is

cover construction requirements for various environmental

coiled around a spool. The tape is rolled out and progressively

conditions. Figure 10-73 shows examples of three of the most

pushed through the conduit until it protrudes out the far end.

common NEMA enclosures. NEMA 1 is for indoor, relatively

The wires are looped around the wire hook and taped smooth.

The fish tape is then pulled back through the conduit, along

with the wires.

For any given conduit size, a limited number of conductors

can be installed. The chart given in Figure 10-77 shows the

maximum number of thermoplastic high heat resistant nylon

coated (THHN) conductors that any given size of conduit can

typically support.

Raceway Systems

NEMA 1

NEMA 3R

NEMA 4 and 4X

In some applications it is necessary or desirable to surface

Figure 10-73 NEMA Standard Enclosures mount an electrical system. Raceway systems, as shown in