Page 224 - Electromechanical Devices and Components Illustrated Sourcebook

P. 224

186 Electromechanical Devices & Components Illustrated Sourcebook

Upper Alignment

Plate (PTFE)

High Voltage × ISO Flange

Flood with

Epoxy Glue

Two Pole

High Current

× 40 Series

NPT Bull Plug

Quick Flange

BNC × 25 Series

Quick Flange

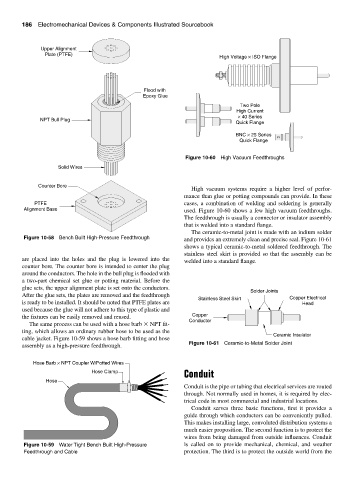

Figure 10-60 High Vacuum Feedthroughs

Solid Wires

Counter Bore

High vacuum systems require a higher level of perfor-

mance than glue or potting compounds can provide. In these

PTFE cases, a combination of welding and soldering is generally

Alignment Base used. Figure 10-60 shows a few high vacuum feedthroughs.

The feedthrough is usually a connector or insulator assembly

that is welded into a standard flange.

The ceramic-to-metal joint is made with an indium solder

Figure 10-58 Bench Built High-Pressure Feedthrough

and provides an extremely clean and precise seal. Figure 10-61

shows a typical ceramic-to-metal soldered feedthrough. The

stainless steel skirt is provided so that the assembly can be

are placed into the holes and the plug is lowered into the

welded into a standard flange.

counter bore. The counter bore is intended to center the plug

around the conductors. The hole in the bull plug is flooded with

a two-part chemical set glue or potting material. Before the

glue sets, the upper alignment plate is set onto the conductors.

Solder Joints

After the glue sets, the plates are removed and the feedthrough

Stainless Steel Skirt Copper Electrical

is ready to be installed. It should be noted that PTFE plates are Head

used because the glue will not adhere to this type of plastic and

the fixtures can be easily removed and reused. Copper

Conductor

The same process can be used with a hose barb NPT fit-

ting, which allows an ordinary rubber hose to be used as the

Ceramic Insulator

cable jacket. Figure 10-59 shows a hose barb fitting and hose

assembly as a high-pressure feedthrough. Figure 10-61 Ceramic-to-Metal Solder Joint

Hose Barb × NPT Coupler W/Potted Wires

Conduit

Hose Clamp

Hose

Conduit is the pipe or tubing that electrical services are routed

through. Not normally used in homes, it is required by elec-

trical code in most commercial and industrial locations.

Conduit serves three basic functions, first it provides a

guide through which conductors can be conveniently pulled.

This makes installing large, convoluted distribution systems a

much easier proposition. The second function is to protect the

wires from being damaged from outside influences. Conduit

Figure 10-59 Water Tight Bench Built High-Pressure is called on to provide mechanical, chemical, and weather

Feedthrough and Cable protection. The third is to protect the outside world from the