Page 250 - Electromechanical Devices and Components Illustrated Sourcebook

P. 250

212 Electromechanical Devices & Components Illustrated Sourcebook

Most of us would agree that the electric light ranks as one of

Argon Gas

the most important technological developments that man has

ever achieved. It was in the early 1800s that electric lighting Tungsten Wire

began to appear in cities around the world. These early lamps

used an electric arc to produce a brilliant light that was suit- Test Tube

able for outdoor applications. However, because these lamps

could only operate at high power levels, they were not suit-

able for indoor use. Early movie projectors relied on arc

lamps to produce the high intensity light required to project

motion pictures. During World War II, arc lamps were used High Temperature Cork

extensively to spotlight enemy aircraft flying over England at

night. Terminal Wires

In the late 1800s, Thomas Edison invented the first practi-

cal incandescent light bulb. The difficulty in developing a Figure 12-2 Simple, Bench Built Incandescent Light

light bulb came in the filament. Metals simply couldn’t oper- Bulb

ate at the temperatures required without melting and then

evaporating. After trying thousands of configurations with all

types of plant matter, Edison finally developed a filament Figure 12-3 shows a modern incandescent light bulb with

made up of a cotton thread that was coated and embedded a screw base. These bulbs differ very little from early units.

with carbon granules. When placed in a low pressure, inert They have a coiled tungsten filament, which operates in an

gas environment, the filament was able to glow brightly for inert gas environment. The gas is usually argon at approxi-

long periods of time. mately 80% of atmospheric pressure. The lower pressure is

intended to bring the internal pressure back up to atmospheric

pressure when the bulb is at full operating temperature.

Incandescent Lights Modern bulbs generally have a white diffuser coating in the

inside to better distribute and soften the light.

Figure 12-1 shows an early incandescent light bulb and base.

These units were supplied with a clear glass bulb which

enclosed a long filament. The inside of the bulb is filled with

a low pressure, inert gas. The filament is connected to two

Diffuser

heavy wire terminals that are sealed into the base of the bulb. Coating

A third wire is used to support the rather fragile filament.

Glass

Coiled Tungsten Bulb

Filament

Glass Bulb

Inert Gas

Low-Pressure

Inert Gas Filament Filament Support

Filament Support Filament Wires

Filament Terminal

Base

Screw Base

Terminals

Figure 12-1 Early Incandescent Light Bulb Center Terminal

Figure 12-3 Commercial Incandescent Light Bulb

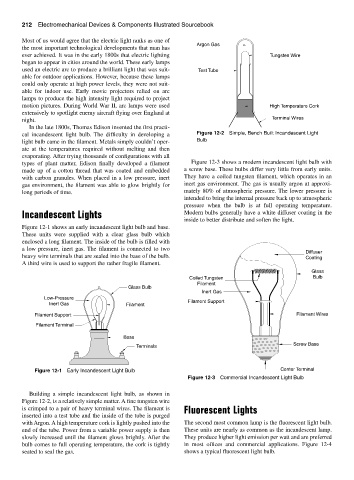

Building a simple incandescent light bulb, as shown in

Figure 12-2, is a relatively simple matter. A fine tungsten wire

is crimped to a pair of heavy terminal wires. The filament is Fluorescent Lights

inserted into a test tube and the inside of the tube is purged

with Argon. A high temperature cork is lightly pushed into the The second most common lamp is the fluorescent light bulb.

end of the tube. Power from a variable power supply is then These units are nearly as common as the incandescent lamp.

slowly increased until the filament glows brightly. After the They produce higher light emission per watt and are preferred

bulb comes to full operating temperature, the cork is tightly in most offices and commercial applications. Figure 12-4

seated to seal the gas. shows a typical fluorescent light bulb.