Page 273 - Electromechanical Devices and Components Illustrated Sourcebook

P. 273

Chapter 13 Meters 235

Moving Jaw Fixed Jaw Moving Jaw Fixed Jaw

20 50

10 100

Pivot Range Selector

500 AMPS MAX. Palm Grip Trigger 7 6 5 14 12 10 35 Multirange Scale

45

Trigger −10 9 8 20 18 16 50

40

30

25

Handle

15

10

2 4 3 8 6 4 20 Pointer

1 2 5

0 0 0

Bend Relief

Test Lead Wire Figure 13-40 Hand Held Inductive Current Meter

Output Terminals

(M) Banana Plugs

Figure 13-38 Inductive Pickup

Through Hole

Cable to be

Moving Core or Jaw Monitored Secondary Coil

Iron Core

Secondary

Base

Figure 13-41 Commercial Current Transformer

Volt Meter

Voltmeter

Pivot

Cable in which

Current is to be Measured

Figure 13-39 Inductive Pickup Schematic

Flow of Current

Shunt Resistor

Figure 13-42 Current Shunt Schematic

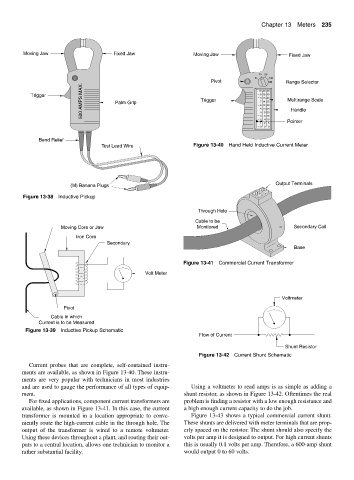

Current probes that are complete, self-contained instru-

ments are available, as shown in Figure 13-40. These instru-

ments are very popular with technicians in most industries

and are used to gauge the performance of all types of equip- Using a voltmeter to read amps is as simple as adding a

ment. shunt resistor, as shown in Figure 13-42. Oftentimes the real

For fixed applications, component current transformers are problem is finding a resistor with a low enough resistance and

available, as shown in Figure 13-41. In this case, the current a high enough current capacity to do the job.

transformer is mounted in a location appropriate to conve- Figure 13-43 shows a typical commercial current shunt.

niently route the high-current cable in the through hole. The These shunts are delivered with meter terminals that are prop-

output of the transformer is wired to a remote voltmeter. erly spaced on the resistor. The shunt should also specify the

Using these devices throughout a plant, and routing their out- volts per amp it is designed to output. For high current shunts

puts to a central location, allows one technician to monitor a this is usually 0.1 volts per amp. Therefore, a 600-amp shunt

rather substantial facility. would output 0 to 60 volts.