Page 295 - Elements of Chemical Reaction Engineering 3rd Edition

P. 295

Sec. !j.7 Evaluation of Laboratory Reactors 267

t

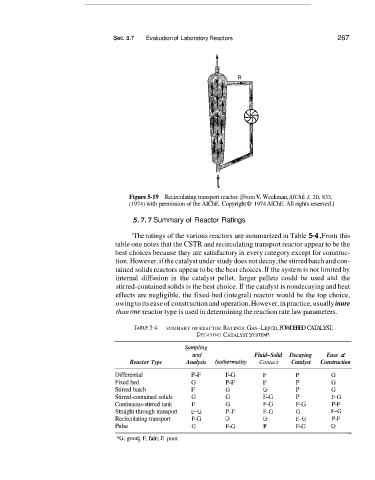

Figure 5-19 Recirculating transport reactor. [From V. Weekman, AKhh J. 20, 833,

(1974) with permission of the AIChE. Copyright 0 1974 AIChE. All rights reserved.]

5.7.7 Summary of Reactor Ratings

'The ratings of the various reactors are summarized in Table 5-4. From this

table one notes that the CSTR and recirculating transport reactor appear to be the

best choices because they are satisfactory in every category except for construc-

tion. However, if the catalyst under study does not decay, the stirred batch and con-

tained solids reactors appear to be the best choices. If the system is not limited by

internal diffusion in the catalyst pellet, larger pellets could be used and the

stirred-contained solids is the best choice. If the catalyst is nondecaying and heat

effects are negligible, the fixed-bed (integral) reactor would be the top choice,

owing to its ease of construction and operation. However, in practice, usually inure

than one reactor type is used in determining the reaction rate law parameters.

FrABLE 5-4. SUMMARY OF REACTOR RATINGS: GAS-LIQUID, POWDERED CATALYST,

C

DIECAVING ATALYST SYSTEM^

Sampling

and Fluid-Solid Decaying Ease of

Reactor Type Analysis Isothermaliry Contact Catalyst Construction

-

Differential P-F F-G F P G

Fixed bed G P-F F P G

Stirred batch F G G P G

Stirred-contained solids G G F-G P F-G

Continuous-stirred tank F G F-G F-G P-F

Straight-through transport F-G P-F F-G G F-G

Recirculating transport F-G G G F-G P-F

Pulse G F-G P F-G G

-

aG, goock F, fair; P, poor.