Page 511 - Elements of Chemical Reaction Engineering Ebook

P. 511

Sec. 8.5 Nonadiabatic Reactor Operation: Oxidation of Sulfur Dioxide Example 481

' - 1

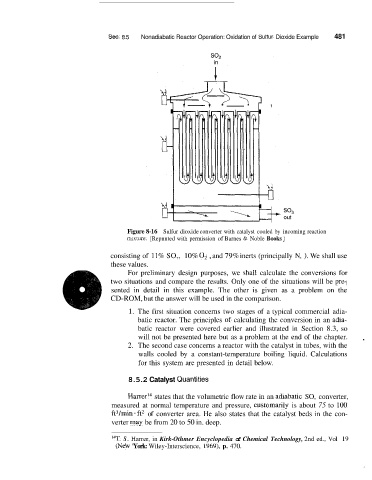

Figure 8-16 Sulfur dioxide converter with catalyst cooled by incoming reaction

nuxture. [Repnnted with permission of Barnes & Noble Books ]

consisting of 11% SO,, 10% 0, , and 79% inerts (principally N, >. We shall use

these values.

For preliminary design purposes, we shalI calculate the conversions for

two situations and compare the results. Only one of the situations will be lpre-

sented in detail in this example. The other is given as a problem on the

CD-ROM, but the answer will be used in the comparison.

1. The first situation concerns two stages of a typical commercial adia-

batic reactor. The principles of calculating the conversion in an aldia-

batic reactor were covered earlier and illustrated in Section 8.3, so

will not be presented here but as a problem at the end of the chapter.

2. The second case concerns a reactor with the catalyst in tubes, with the '

walls cooled by a constant-temperature boiling liquid. Calculations

for this system are presented in detail below.

8.5.2 Catalyst Quantities

Harrer14 states that the volumetric flow rate in an a&abatic SO, converter,

measured at normal temperature and pressure, customarily is about 75 to 100

ft3/min-ft2 of converter area. He also states that the catalyst beds in the con-

verter rnay be from 20 to 50 in. deep.

I4T. S. Harrer, in Kirk-Othmer Encyclopedia of Chemical Technology, 2nd ed., Vol 19

(Neh 'York: Wiley-Interscience, 1969), p. 470.