Page 245 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 245

P1: GLQ/GLE P2: GPB Final Pages

Encyclopedia of Physical Science and Technology EN014J-683 July 30, 2001 20:3

Separation and Purification of Biochemicals 653

design and validation of standard operating procedures the bioproduct is separated from the producing organisms

(SOP), between batch in-place cleaning (CIP), and san- and other insolubles by a solid/liquid separation step, such

itizing (SIP) procedures or the validation of operational ascentrifugationorfiltration.Thismayrequirecellrupture

parameters such as column leaching and the necessity to in the case of intracellularly enriched substances or resol-

remove certain impurities (endotoxins, virus DNA, etc.) ubilization in the case of inclusion bodies. In the second

havetobetakenintoaccount.Themainregulatoryconcern isolation step, substances that differ considerably in their

is the possibility of contamination of the product with any physicochemical character are removed from the prod-

substance whose administration could be detrimental to uct. The methods used are either highly specific, based

the patient. on biospecific (affinity) interactions or substance class

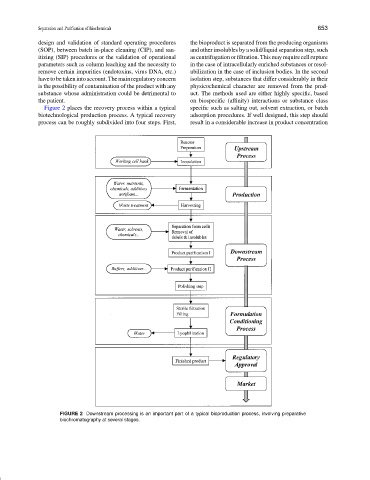

Figure 2 places the recovery process within a typical specific such as salting out, solvent extraction, or batch

biotechnological production process. A typical recovery adsorption procedures. If well designed, this step should

process can be roughly subdivided into four steps. First, result in a considerable increase in product concentration

FIGURE 2 Downstream processing is an important part of a typical bioproduction process, involving preparative

biochromatography at several stages.