Page 143 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 143

P1: ZCK/FLS P2: FYK/FLS QC: FYK Revised Pages

Encyclopedia of Physical Science and Technology EN002G-100 May 19, 2001 18:49

Chemical Process Design, Simulation, Optimization, and Operation 765

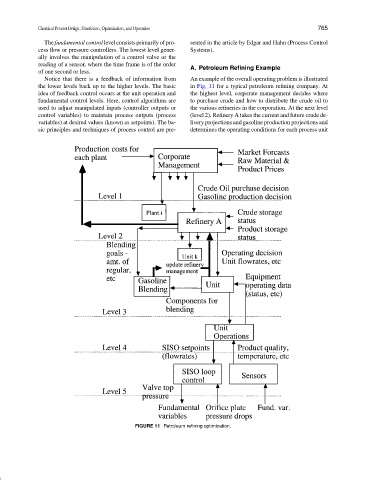

The fundamental control level consists primarily of pro- sented in the article by Edgar and Hahn (Process Control

cess flow or pressure controllers. The lowest level gener- Systems).

ally involves the manipulation of a control valve or the

reading of a sensor, where the time frame is of the order

A. Petroleum Refining Example

of one second or less.

Notice that there is a feedback of information from An example of the overall operating problem is illustrated

the lower levels back up to the higher levels. The basic in Fig. 11 for a typical petroleum refining company. At

idea of feedback control occurs at the unit operation and the highest level, corporate management decides where

fundamental control levels. Here, control algorithms are to purchase crude and how to distribute the crude oil to

used to adjust manipulated inputs (controller outputs or the various refineries in the corporation. At the next level

control variables) to maintain process outputs (process (level 2), Refinery A takes the current and future crude de-

variables) at desired values (known as setpoints). The ba- livery projections and gasoline production projections and

sic principles and techniques of process control are pre- determines the operating conditions for each process unit

FIGURE 11 Petroleum refining optimization.