Page 138 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 138

P1: ZCK/FLS P2: FYK/FLS QC: FYK Revised Pages

Encyclopedia of Physical Science and Technology EN002G-100 May 19, 2001 18:49

760 Chemical Process Design, Simulation, Optimization, and Operation

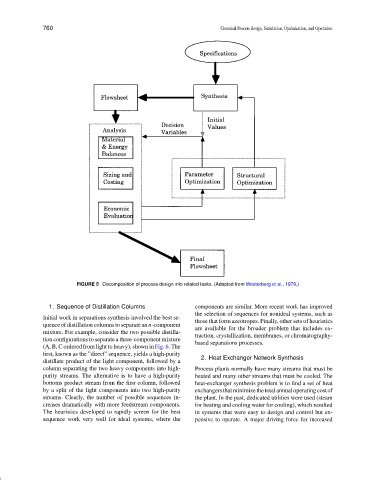

FIGURE 5 Decomposition of process design into related tasks. (Adapted from Westerberg et al., 1979.)

1. Sequence of Distillation Columns components are similar. More recent work has improved

the selection of sequences for nonideal systems, such as

Initial work in separations synthesis involved the best se-

those that form azeotropes. Finally, other sets of heuristics

quence of distillation columns to separate an n-component

are available for the broader problem that includes ex-

mixture. For example, consider the two possible distilla-

traction, crystallization, membranes, or chromatography-

tion configurations to separate a three-component mixture

based separations processes.

(A, B, C ordered from light to heavy), shown in Fig. 6. The

first, known as the ”direct” sequence, yields a high-purity 2. Heat Exchanger Network Synthesis

distillate product of the light component, followed by a

column separating the two heavy components into high- Process plants normally have many streams that must be

purity streams. The alternative is to have a high-purity heated and many other streams that must be cooled. The

bottoms product stream from the first column, followed heat-exchanger synthesis problem is to find a set of heat

by a split of the light components into two high-purity exchangersthatminimizethetotalannualoperatingcostof

streams. Clearly, the number of possible sequences in- the plant. In the past, dedicated utilities were used (steam

creases dramatically with more feedstream components. for heating and cooling water for cooling), which resulted

The heuristics developed to rapidly screen for the best in systems that were easy to design and control but ex-

sequence work very well for ideal systems, where the pensive to operate. A major driving force for increased