Page 133 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 133

P1: ZCK/FLS P2: FYK/FLS QC: FYK Revised Pages

Encyclopedia of Physical Science and Technology EN002G-100 May 19, 2001 18:49

Chemical Process Design, Simulation, Optimization, and Operation 755

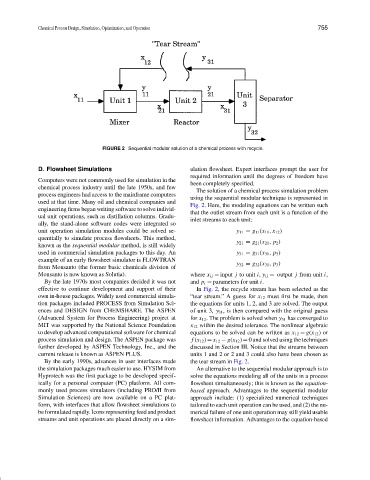

FIGURE 2 Sequential modular solution of a chemical process with recycle.

D. Flowsheet Simulations ulation flowsheet. Expert interfaces prompt the user for

required information until the degrees of freedom have

Computers were not commonly used for simulation in the

been completely specified.

chemical process industry until the late 1950s, and few

The solution of a chemical process simulation problem

process engineers had access to the mainframe computers

using the sequential modular technique is represented in

used at that time. Many oil and chemical companies and

Fig. 2. Here, the modeling equations can be written such

engineering firms began writing software to solve individ-

that the outlet stream from each unit is a function of the

ual unit operations, such as distillation columns. Gradu-

inlet streams to each unit:

ally, the stand-alone software codes were integrated so

unit operation simulation modules could be solved se- y 11 = g 11 (x 11 , x 12 )

quentially to simulate process flowsheets. This method,

y 21 = g 21 (x 21 , p 2 )

known as the sequential modular method, is still widely

used in commercial simulation packages to this day. An y 31 = g 31 (x 31 , p 3 )

example of an early flowsheet simulator is FLOWTRAN

y 32 = g 32 (x 31 , p 3 )

from Monsanto (the former basic chemicals division of

Monsanto is now known as Solutia). where x ij = input j to unit i, y ij = output j from unit i,

By the late 1970s most companies decided it was not and p i = parameters for unit i.

effective to continue development and support of their In Fig. 2, the recycle stream has been selected as the

own in-house packages. Widely used commercial simula- “tear stream.” A guess for x 12 must first be made, then

tion packages included PROCESS from Simulation Sci- the equations for units 1, 2, and 3 are solved. The output

ences and DESIGN from CHEMSHARE. The ASPEN of unit 3, y 31 , is then compared with the original guess

(Advanced System for Process Engineering) project at for x 12 . The problem is solved when y 31 has converged to

MIT was supported by the National Science Foundation x 12 within the desired tolerance. The nonlinear algebraic

to develop advanced computational software for chemical equations to be solved can be written as x 12 = g(x 12 )or

process simulation and design. The ASPEN package was f (x 12 ) = x 12 − g(x 12 ) = 0 and solved using the techniques

further developed by ASPEN Technology, Inc., and the discussed in Section III. Notice that the streams between

current release is known as ASPEN PLUS. units 1 and 2 or 2 and 3 could also have been chosen as

By the early 1990s, advances in user interfaces made the tear stream in Fig. 2.

the simulation packages much easier to use. HYSIM from An alternative to the sequential modular approach is to

Hyprotech was the first package to be developed specif- solve the equations modeling all of the units in a process

ically for a personal computer (PC) platform. All com- flowsheet simultaneously; this is known as the equation-

monly used process simulators (including PRO/II from based approach. Advantages to the sequential modular

Simulation Sciences) are now available on a PC plat- approach include: (1) specialized numerical techniques

form, with interfaces that allow flowsheet simulations to tailored to each unit operation can be used, and (2) the nu-

be formulated rapidly. Icons representing feed and product merical failure of one unit operation may still yield usable

streams and unit operations are placed directly on a sim- flowsheet information. Advantages to the equation-based