Page 130 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 130

P1: ZCK/FLS P2: FYK/FLS QC: FYK Revised Pages

Encyclopedia of Physical Science and Technology EN002G-100 May 19, 2001 18:49

752 Chemical Process Design, Simulation, Optimization, and Operation

temperature of a process feedstream by using steam as Plastics and polymeric materials

a heating media. Air products (oxygen, nitrogen, etc.)

Consumer products (detergents, etc.)

Agricultural chemicals

I. BACKGROUND Pharmaceuticals

Inorganic chemicals (sodium hydroxide, etc.)

The field of process systems engineering refers to the Textiles

varioustechniquestodesign,simulate,optimize,andoper- Minerals processing

ate chemical processes. A majority of chemical processes Biotechnology

operate in a continuous fashion; that is, raw material is Electronic materials and semiconductor device

continuouslyfedtothemanufacturingprocessandproduct

manufacturing

is continuously produced. Large manufacturing processes

often run for 18 months or more without any major shut-

In this article, we provide an overview of a number of

down. For this reason, most process systems engineering

techniques used by process engineers. We will provide

techniques have been applied to continuous processes,

references to numerous sources for details of the method-

which are the focus of this article. Batch processes are

ologies or applications.

presented elsewhere.

Many consumer products are produced, at least in

part, using chemical processes. A characteristic chemical II. PROCESS MODELS

process involves a chemical and/or physical transforma-

tion of raw materials into products or intermediates that In order to make design or operation decisions a process

are then further processed. Process flowsheets or process engineer uses a process model. A process model is a set of

flow diagrams are used by process engineers to depict mathematical equations that allows one to predict the be-

the flow of process streams through the basic unit oper- havior of a chemical process system. Mathematical mod-

ations involved in a chemical manufacturing process. A els can be fundamental, empirical, or (more often) a com-

unit operation typically refers to a vessel where a chem- bination of the two. Fundamental models are based on

ical or physical transformation occurs. Examples include known physical–chemical relationships, such as the con-

chemical reactors and distillation columns. servation of mass and energy, as well as thermodynamic

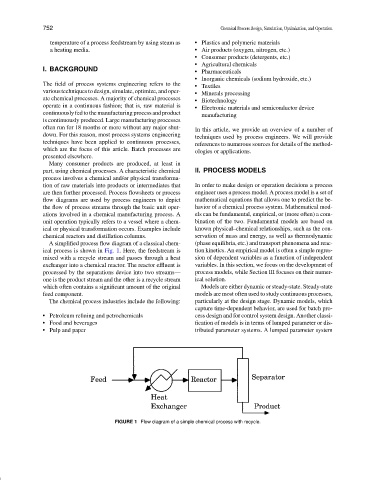

A simplified process flow diagram of a classical chem- (phase equilibria, etc.) and transport phenomena and reac-

ical process is shown in Fig. 1. Here, the feedstream is tion kinetics. An empirical model is often a simple regres-

mixed with a recycle stream and passes through a heat sion of dependent variables as a function of independent

exchanger into a chemical reactor. The reactor effluent is variables. In this section, we focus on the development of

processed by the separations device into two streams— process models, while Section III focuses on their numer-

one is the product stream and the other is a recycle stream ical solution.

which often contains a significant amount of the original Models are either dynamic or steady-state. Steady-state

feed component. models are most often used to study continuous processes,

The chemical process industries include the following: particularly at the design stage. Dynamic models, which

capture time-dependent behavior, are used for batch pro-

Petroleum refining and petrochemicals cess design and for control system design. Another classi-

Food and beverages fication of models is in terms of lumped parameter or dis-

Pulp and paper tributed parameter systems. A lumped parameter system

FIGURE 1 Flow diagram of a simple chemical process with recycle.