Page 234 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 234

P1: GJC Final Pages

Encyclopedia of Physical Science and Technology EN004E-182 June 8, 2001 18:16

558 Distillation

TABLE III (continued)

Total U.S. Specific

distillation distillation

energy energy

consumption consumption

Component classification (quads/yr) a (Btu/lb product)

Ethylbenzene 0.01388 2264

o-Xylene 0.00638 6019

Cumene 0.00390 1450

Total 0.06407 1515

Water-inorganics

Sour water strippers 0.02742 240

Sodium carbonate 0.01398 1875

Urea 0.01030 133

Total 0.05170 411

Others

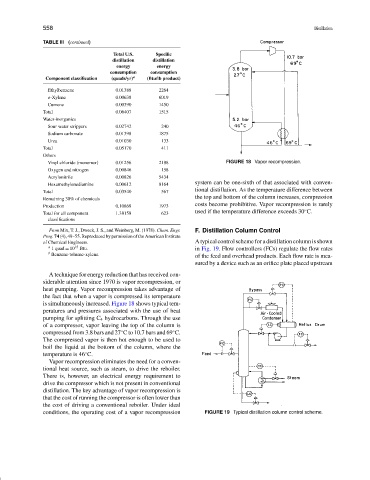

Vinyl chloride (monomer) 0.01256 2188 FIGURE 18 Vapor recompression.

Oxygen and nitrogen 0.00846 158

Acrylonitrile 0.00826 5434

system can be one-sixth of that associated with conven-

Hexamethylenediamine 0.00612 8164

tional distillation. As the temperature difference between

Total 0.03540 567

the top and bottom of the column increases, compression

Remaining 30% of chemicals

costs become prohibitive. Vapor recompression is rarely

Production 0.10869 1973

◦

used if the temperature difference exceeds 30 C.

Total for all component 1.38158 623

classifications

From Mix, T. J., Dweck, J. S., and Weinberg, M. (1978). Chem. Engr. F. Distillation Column Control

Prog. 74 (4), 49–55. Reproduced by permission of the American Institute

of Chemical Engineers. A typical control scheme for a distillation column is shown

a 15

1 quad = 10 Btu. in Fig. 19. Flow controllers (FCs) regulate the flow rates

b

Benzene-toluene-xylene. of the feed and overhead products. Each flow rate is mea-

sured by a device such as an orifice plate placed upstream

A technique for energy reduction that has received con-

siderable attention since 1970 is vapor recompression, or

heat pumping. Vapor recompression takes advantage of

the fact that when a vapor is compressed its temperature

is simultaneously increased. Figure 18 shows typical tem-

peratures and pressures associated with the use of heat

pumping for splitting C 4 hydrocarbons. Through the use

of a compressor, vapor leaving the top of the column is

◦

compressed from 3.8 bars and 27 C to 10.7 bars and 69 C.

◦

The compressed vapor is then hot enough to be used to

boil the liquid at the bottom of the column, where the

temperature is 46 C.

◦

Vapor recompression eliminates the need for a conven-

tional heat source, such as steam, to drive the reboiler.

There is, however, an electrical energy requirement to

drive the compressor which is not present in conventional

distillation. The key advantage of vapor recompression is

that the cost of running the compressor is often lower than

the cost of driving a conventional reboiler. Under ideal

conditions, the operating cost of a vapor recompression FIGURE 19 Typical distillation column control scheme.