Page 233 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 233

P1: GJC Final Pages

Encyclopedia of Physical Science and Technology EN004E-182 June 8, 2001 18:16

Distillation 557

been increasingly employed inside distillation columns TABLE III Distillation Energy Consumption

to simultaneously effect distillation and reaction. Oxy-

Total U.S. Specific

genates such as methyl-tert-butyl-ether (MTBE) and distillation distillation

tertiary-methyl-ether (TAME) are produced in this man- energy energy

ner for utilization within reformulated gasolines (RFGs). consumption consumption

Component classification (quads/yr) a (Btu/lb product)

In reactive distillation, catalysts can be employed between

the sheets of structured packings, on the decks or inside Petroleum fuel fractions

the downcomers of trays, or in dedicated beds between Crude distillation 0.36115 193

packed or trayed column sections. It is expected that reac- Vacuum distillation 0.08990 132

tive distillation will be used even more extensively in the Catalytic hydrotreating/ 0.07726 101

future. hydrorefining

Catalytic cracking fractionator 0.06803 112

Naphtha fractionator 0.06105 132

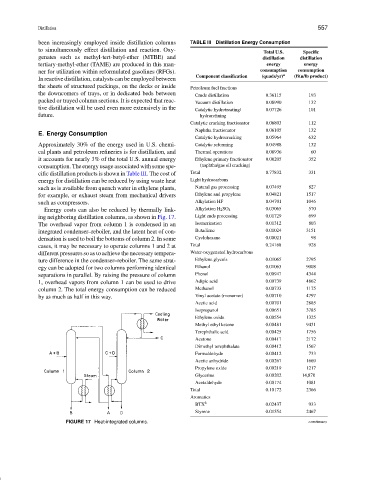

E. Energy Consumption

Catalytic hydrocracking 0.05964 632

Approximately 30% of the energy used in U.S. chemi- Catalytic reforming 0.04988 132

cal plants and petroleum refineries is for distillation, and Thermal operations 0.00936 60

it accounts for nearly 3% of the total U.S. annual energy Ethylene primary fractionator 0.00205 352

consumption. The energy usage associated with some spe- (naphtha/gas oil cracking)

cific distillation products is shown in Table III. The cost of Total 0.77832 331

energy for distillation can be reduced by using waste heat Light hydrocarbons

such as is available from quench water in ethylene plants, Natural gas processing 0.07495 827

for example, or exhaust steam from mechanical drivers Ethylene and propylene 0.04821 1517

such as compressors. Alkylation HF 0.04701 1046

Energy costs can also be reduced by thermally link- Alkylation H 2 SO 4 0.03065 570

ing neighboring distillation columns, as shown in Fig. 17. Light ends processing 0.01729 699

The overhead vapor from column 1 is condensed in an Isomerization 0.01312 803

integrated condenser–reboiler, and the latent heat of con- Butadiene 0.01024 3151

densation is used to boil the bottoms of column 2. In some Cyclohexane 0.00021 98

cases, it may be necessary to operate columns 1 and 2 at Total 0.24168 928

different pressures so as to achieve the necessary tempera- Water-oxygenated hydrocarbons

ture difference in the condenser–reboiler. The same strat- Ethylene glycols 0.01065 2795

egy can be adopted for two columns performing identical Ethanol 0.01063 9008

separations in parallel. By raising the pressure of column Phenol 0.00947 4344

1, overhead vapors from column 1 can be used to drive Adipic acid 0.00739 4862

column 2. The total energy consumption can be reduced Methanol 0.00733 1175

by as much as half in this way. Vinyl acetate (monomer) 0.00710 4797

Acetic acid 0.00701 2885

Isopropanol 0.00651 3785

Ethylene oxide 0.00554 1325

Methyl ethyl ketone 0.00481 9431

Terephthalic acid 0.00425 1756

Acetone 0.00417 2172

Dimethyl terephthalate 0.00412 1567

Formaldehyde 0.00412 733

Acetic anhydride 0.00267 1669

Propylene oxide 0.00219 1217

Glycerine 0.00202 14,870

Acetaldehyde 0.00174 1081

Total 0.10172 2366

Aromatics

BTX b 0.02437 933

Styrene 0.01554 2467

FIGURE 17 Heat-integrated columns. continues