Page 16 - Academic Press Encyclopedia of Physical Science and Technology 3rd Organic Chemistry

P. 16

P1: GLQ Revised Pages

Encyclopedia of Physical Science and Technology EN001F-4 May 7, 2001 16:19

68 Acetylene

for the production of 300 million pounds of acetylene per

year has been reported by SRI International, together with

detailed economics and process diagrams.

IX. CHEMISTRY OF SPECIALTY

PRODUCTS

The chemical compounds discussed in this section are

either acetylenics or their derivatives. Often, acetylene

is a building block in the synthesis of a more complex

molecule and is not recognizable as such in the final com-

pound. Products such as vitamins A and E examplify this.

Specialty chemicals derived from acetylene have varied

and selective uses, and their market size can vary from

thousands of pounds to millions of pounds per year.

A. Ethynylation Reaction

The introduction of an acetylenic group ( CH CH or

C C ) was called ethynylation in Reppe days, and the

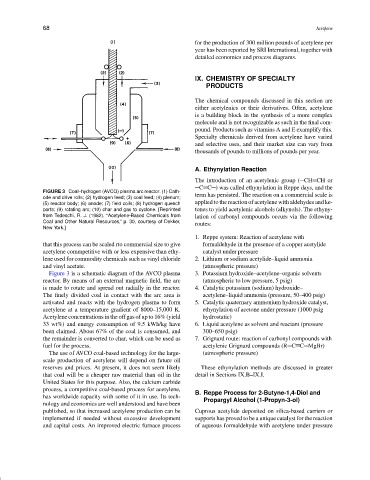

FIGURE 3 Coal–hydrogen (AVCO) plasma arc reactor. (1) Cath-

term has persisted. The reaction on a commercial scale is

ode and drive rolls; (2) hydrogen feed; (3) coal feed; (4) plenum;

(5) reactor body; (6) anode; (7) field coils; (8) hydrogen quench applied to the reaction of acetylene with aldehydes and ke-

ports; (9) rotating arc; (10) char and gas to cyclone. [Reprinted tones to yield acetylenic alcohols (alkynols). The ethyny-

from Tedeschi, R. J. (1982). “Acetylene-Based Chemicals from lation of carbonyl compounds occurs via the following

Coal and Other Natural Resources,” p. 30, courtesy of Dekker, routes:

New York.]

1. Reppe system: Reaction of acetylene with

that this process can be scaled rto commercial size to give formaldehyde in the presence of a copper acetylide

acetylene commpetitive with or less expensive than ethy- catalyst under pressure

lene used for commodity chemicals such as vinyl chloride 2. Lithium or sodium acetylide–liquid ammonia

and vinyl acetate. (atmospheric pressure)

Figure 3 is a schematic diagram of the AVCO plasma 3. Potassium hydroxide–acetylene–organic solvents

reactor. By means of an external magnetic field, the arc (atmospheric to low pressure, 5 psig)

is made to rotate and spread out radially in the reactor. 4. Catalytic potassium (sodium) hydroxide–

The finely divided coal in contact with the arc area is acetylene–liquid ammonia (pressure, 50–400 psig)

activated and reacts with the hydrogen plasma to form 5. Catalytic quaternary ammonium hydroxide catalyst,

acetylene at a temperature gradient of 8000–15,000 K. ethynylation of acetone under pressure (1000 psig

Acetylene concentrations in the off gas of up to 16% (yield hydrostatic)

33 wt%) and energy consumption of 9.5 kWh/kg have 6. Liquid acetylene as solvent and reactant (pressure

been claimed. About 67% of the coal is consumed, and 300–650 psig)

the remainder is converted to char, which can be used as 7. Grignard route: reaction of carbonyl compounds with

fuel for the process. acetylenic Grignard compounds (R C C MgBr)

The use of AVCO coal-based technology for the large- (atmospheric pressure)

scale production of acetylene will depend on future oil

reserves and prices. At present, it does not seem likely These ethynylation methods are discussed in greater

that coal will be a cheaper raw material than oil in the detail in Sections IX.B–IX.I.

United States for this purpose. Also, the calcium carbide

process, a competitive coal-based process for acetylene,

B. Reppe Process for 2-Butyne-1,4-Diol and

has worldwide capacity with some of it in use. Its tech-

Propargyl Alcohol (1-Propyn-3-ol)

nology and economics are well understood and have been

published, so that increased acetylene production can be Cuprous acetylide deposited on silica-based carriers or

implemented if needed without excessive development supports has proved to be a unique catalyst for the reaction

and capital costs. An improved electric furnace process of aqueous formaldehyde with acetylene under pressure