Page 18 - Academic Press Encyclopedia of Physical Science and Technology 3rd Organic Chemistry

P. 18

P1: GLQ Revised Pages

Encyclopedia of Physical Science and Technology EN001F-4 May 7, 2001 16:19

70 Acetylene

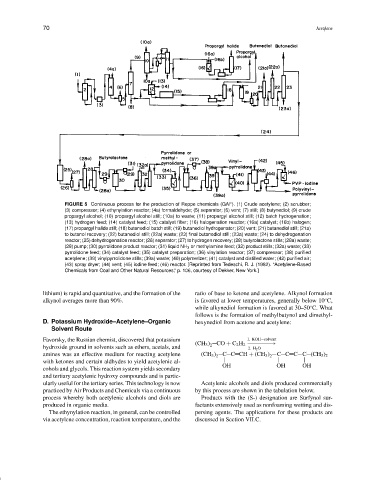

FIGURE 5 Continuous process for the production of Reppe chemicals (GAF). (1) Crude acetylene; (2) scrubber;

(3) compressor; (4) ethynylation reactor; (4a) formaldehyde; (5) separator; (6) vent; (7) still; (8) butynediol; (9) crude

propargyl alcohol; (10) propargyl alcohol still; (10a) to waste; (11) propargyl alcohol still; (12) batch hydrogenation;

(13) hydrogen feed; (14) catalyst feed; (15) catalyst filter; (16) halogenation reactor; (16a) catalyst; (16b) halogen;

(17) propargyl halide still; (18) butenediol batch still; (19) butanediol hydrogenator; (20) vent; (21) butanediol still; (21a)

to butanol recovery; (22) butanediol still; (22a) waste; (23) final butanediol still; (23a) waste; (24) to dehydrogenation

reactor; (25) dehydrogenation reactor; (26) separator; (27) to hydrogen recovery; (28) butyrolactone stills; (28a) waste;

(29) pump; (30) pyrrolidone product reactor; (31) liquid NH 3 or methylamine feed; (32) product stills; (32a) waste; (33)

pyrrolidone feed; (34) catalyst feed; (35) catalyst preparation; (36) vinylation reactor; (37) compressor; (38) purified

acetylene; (39) vinylpyrrolidone stills; (39a) waste; (40) polymerizer; (41) catalyst and distilled water; (42) purified air;

(43) spray dryer; (44) vent; (45) iodine feed; (46) reactor. [Reprinted from Tedeschi, R. J. (1982). “Acetylene-Based

Chemicals from Coal and Other Natural Resources,” p. 106, courtesy of Dekker, New York.]

lithium) is rapid and quantitative, and the formation of the ratio of base to ketone and acetylene. Alkynol formation

◦

alkynol averages more than 90%. is favored at lower temperatures, generally below 10 C,

while alkynediol formation is favored at 30–50 C. What

◦

follows is the formation of methylbutynol and dimethyl-

D. Potassium Hydroxide–Acetylene–Organic hexynediol from acetone and acetylene:

Solvent Route

Favorsky, the Russian chemist, discovered that potassium 1. KOH−solvent

(CH 3 ) 2 CO + C 2 H 2 −−−−−−−→

hydroxide ground in solvents such as ethers, acetals, and 2. H 2 O

amines was an effective medium for reacting acetylene (CH 3 ) 2 C C CH + (CH 3 ) 2 C C C C (CH 3 ) 2

with ketones and certain aldhydes to yield acetylenic al- | | |

OH OH OH

cohols and glycols. This reaction system yields secondary

and tertiary acetylenic hydroxy compounds and is partic-

ularly useful for the tertiary series. This technology is now Acetylenic alcohols and diols produced commercially

practiced by Air Products and Chemicals via a continuous by this process are shown in the tabulation below.

process whereby both acetylenic alcohols and diols are Products with the (S-) designation are Surfynol sur-

produced in organic media. factants extensively used as nonfoaming wetting and dis-

The ethynylation reaction, in general, can be controlled persing agents. The applications for these products are

via acetylene concentration, reaction temperature, and the discussed in Section VII.C.