Page 15 - Academic Press Encyclopedia of Physical Science and Technology 3rd Organic Chemistry

P. 15

P1: GLQ Revised Pages

Encyclopedia of Physical Science and Technology EN001F-4 May 7, 2001 16:19

Acetylene 67

TABLE IX Acetylene from Natural Gas, Petroleum, and Coal Sources a

Typical process Principal feedstock Technology Typical companies

Electric arc Methane, gas oils Arc or plasma Huels, Du Pont

Sachsse Methane, natural gas mixtures Partial combustion (one stage) BASF, Dow, Monsanto

SBA Methane, natural gas mixtures (first stage); Partial combustion SBA, M. W. Kellogg

naphthas, heavier feedstocks (one and two stage)

(second stage)

Wulff Natural gas, naphthas, heavier feedstocks Regenerative furnace pyrolysis Union Carbide, Wulff

(four cycles)

Montecatini Natural gas, naphthas Partial combustion under pressure Montecatini, Diamond Alkali

By-product acetylene Ethane, hydrocarbons, naphthas, oil Steam cracking Major oil and chemical companies

(EXXON, Shell, Dow, Union Carbide)

Calcium carbide Limestone (CaCO 3 ) and coke CaC 2 from C + CaCO 3 ;C 2 H 2 AIRCO-BOC, Union Carbide

from CaC 2 + H 2 O

AVCO Coal and hydrogen Hydrogen plasma AVCO (pilot and demonstration plants)

a Reprinted from Tedeschi, R. J. (1982). “Acetylene-Based Chemicals from Coal and Other Natural Resources,” p. 11, courtesy of Dekker, New

York.

subjected to an intense energy source and thereby heated stage) and an oxygen–steam off-gas mixture to provide a

to 1200–1500 K. By the use of very short residence times moist flame zone in the lower end of the burner to crack

(0.01–0.001 sec) and quick quenching of the cracked gas naphtha to acetylene. About two-thirds of the hydrocar-

to 550 K, acetylene and the starting feedstock can be re- bon feed is burned in the reactor to provide the thermal

covered. The recovery and purification of petrochemical energy needed to crack the remaining feed to acetylene.

acetylene is a lengthy operation compared with the simple The AVCO coal–hdrogen plasma process has not yet

calcium carbide process, which readily yields high-purity been scaled up to commercial production. However in

acetylene. a joint AVCO–DOE project (1980) at Wilmington, MA,

The petrochemical acetylene processes most likely to a coal-fed hydrogen–plasma reactor capable of produc-

be practiced today are the partial oxidation types. Promi- ing 2 million pounds/year of acetylene was successfully

nent among these are Sachsse, SBA, and Montecatini pro- demonstrated, The pilot unit gave an acetylene yield of

cesses. The SBA and Montecatini processes utilize either 35%basedoncoalwithlowelectricalusage.AVCOclaims

natural gas or naphtha feedstocks, while the Sachsse pro-

cess is designed primarily for natural gas or methane, but

can be modified for naphtha. However, Sachsse technol-

ogy has been widely practiced both in the United States

and in Europe, showing it to be reliable and trouble free.

In contrast, the electric are process is more sensitive

to process variables, which can lead to the formation of

large amounts of by-product carbon. The Wulff process

was once widely used in Europe, South America, Japan,

and the United States. By controlling the feedstock and

operating conditions, the four-cycle regenerative process

could be made to deliver mainly acetylene or ethylene,

making it more versatile than other petrochemical pro-

cesses. The fact that the Wulff process is now seldom used

may be due to the high efficiency of stream cracking of

alkanes to form ethylene and propylene at lower energy

usage, thereby making the Wulff mixed product stream

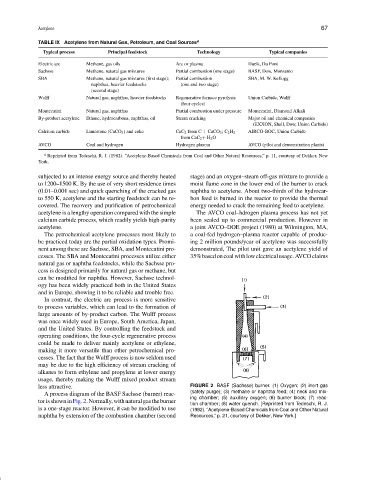

less attractive. FIGURE 2 BASF (Sachsse) burner. (1) Oxygen; (2) inert gas

A process diagram of the BASF Sachsse (burner) reac- (safety purge); (3) methane or naphtha feed; (4) neck and mix-

ing chamber; (5) auxiliary oxygen; (6) burner block; (7) reac-

torisshowninFig.2.Normally,withnaturalgastheburner

tion chamber; (8) water quench. [Reprinted from Tedeschi, R. J.

is a one-stage reactor. However, it can be modified to use (1982). “Acetylene-Based Chemicals from Coal and Other Natural

naphtha by extension of the combustion chamber (second Resources,” p. 21, courtesy of Dekker, New York.]