Page 20 - Academic Press Encyclopedia of Physical Science and Technology 3rd Organic Chemistry

P. 20

P1: GLQ Revised Pages

Encyclopedia of Physical Science and Technology EN001F-4 May 7, 2001 16:19

72 Acetylene

with a β-ionylidene (C 14 ) aldehyde to yield an acetylenic

dihydroxy vitamin A precursor, as illustrated below. In

general, the yields are high and the conditions mild for

the Grignard route. When acetylene is reacted with ethyl-

magnesium bromide, both hydrogen atoms are replaced

and the resulting acetylenedimagnesium bromide is ex-

clusively formed. This di-Grignard can be used to form

sensitive acetylenic diols (see Scheme 1).

H. Use of Basic Quaternary AmmonHium

Hydroxide Resins

Considerable effort has been expended on the develop-

ment of basic resins as replacements for KOH or NaOH in

the catalytic ethynylation of carbonyl compounds. The ob-

jective in the past has been to develop a fixed-bed continu-

ous process in which neutralizaion of the reaction mixture

is not required and product isolation is much simplified.

This type of process has been extensively studied in the

catalytic ethynylation of acetone to form methylbutynol.

The quaternary ammonium hydroxide resin is prepared

from the chloride form of the resin by elution with sodium

hydroxide solution, followed by washing with water, then

methanol washing, and finally vacuum drying. A serious

problem associated with these resins is their degradation

and loss of activity on continued use. Furthermore, alde-

hydes react very poorly and give almost entirely aldol by-

products. Ketones higher than methyl ethyl ketone react so

slowly that the process is not economical. The use of liq-

uid ammonia has been employed to activate the resin and

reactants. However, due to the limited application of this

process, it is doubtful whether this technology is widely

used or whether it is used at all.

I. Use of Liquid Acetylene as Solvent

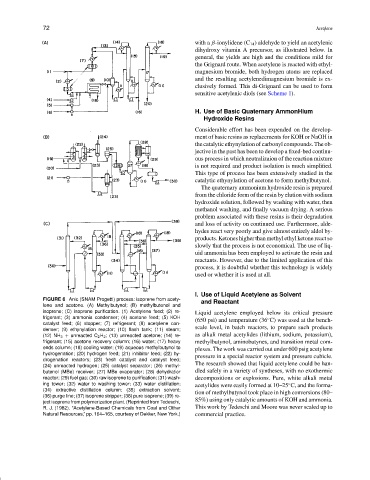

FIGURE 6 Anic (SNAM Progetti) process: isoprene from acety-

and Reactant

lene and acetone. (A) Methylbutynol; (B) methylbutenol and

isoprene; (C) isoprene purification. (1) Acetylene feed; (2) re- Liquid acetylene employed below its critical pressure

frigerant; (3) ammonia condenser; (4) acetone feed; (5) KOH

(650 psi) and temperature (36 C) was used at the bench-

◦

catalyst feed; (6) stopper; (7) refrigerant; (8) acetylene con-

denser; (9) ethynylation reactor; (10) flash tank; (11) steam; scale level, in batch reactors, to prepare such products

(12) NH 3 + unreacted C 2 H 2 ; (13) unreacted acetone; (14) re- as alkali metal acetylides (lithium, sodium, potassium),

frigerant; (15) acetone recovery column; (16) water; (17) heavy methylbutynol, aminobutynes, and transition metal com-

ends column; (18) cooling water; (19) aqueous methylbutynol to plexes. The work was carried out under 600 psig acetylene

hydrogenation; (20) hydrogen feed; (21) inhibitor feed; (22) hy- pressure in a special reactor system and pressure cubicle.

drogenation reactors; (23) fresh catalyst and catalyst feed;

(24) unreacted hydrogen; (25) catalyst separator; (26) methyl- The research showed that liquid acetylene could be han-

butenol (MBe) receiver; (27) MBe evaporator; (28) dehydratior dled safely in a variety of syntheses, with no exothermic

reactor; (29) fuel gas; (30) raw isoprene to purification; (31) wash- decompositions or explosions. Pure, white alkali metal

ing tower; (32) water to washing tower; (33) water distillation; acetylides were easily formed at 10–25 C, and the forma-

◦

(34) extractive distillation column; (35) extraction solvent; tion of methylbutynol took place in high conversions (80–

(36) purge line; (37) isoprene stripper; (38) pure isoprene; (39) re-

ject isoprene from polymerization plant. (Reprinted from Tedeschi, 85%) using only catalytic amounts of KOH and ammonia.

R. J. (1982). “Acetylene-Based Chemicals from Coal and Other This work by Tedeschi and Moore was never scaled up to

Natural Resources,” pp. 164–165, courtesy of Dekker, New York.) commercial practice.