Page 101 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 101

P1: GOX/LBD P2: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN012K-587 July 26, 2001 10:35

Plastics Engineering 471

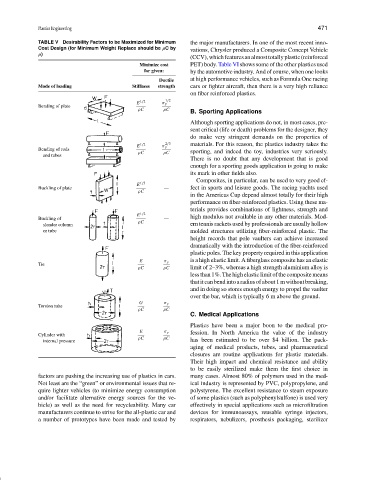

TABLE V Desirability Factors to be Maximized for Minimum the major manufacturers. In one of the most recent inno-

Cost Design (for Minimum Weight Replace should be ρC by vations, Chrysler produced a Composite Concept Vehicle

ρ)

(CCV),whichfeaturesanalmosttotallyplastic(reinforced

Minimize cost PET) body. Table VI shows some of the other plastics used

for given: by the automotive industry. And of course, when one looks

Ductile at high performance vehicles, such as Formula One racing

Mode of loading Stiffness strength cars or fighter aircraft, then there is a very high reliance

on fiber reinforced plastics.

E 1/2 σ y 1/2

Bending of plate

ρC ρC

B. Sporting Applications

Although sporting applications do not, in most cases, pre-

sent critical (life or death) problems for the designer, they

do make very stringent demands on the properties of

E 1/2 σ y 2/3 materials. For this reason, the plastics industry takes the

Bending of rods

ρC ρC sporting, and indeed the toy, industries very seriously.

and tubes

There is no doubt that any development that is good

enough for a sporting goods application is going to make

its mark in other fields also.

Composites, in particular, can be used to very good ef-

E 1/3

Buckling of plate — fect in sports and leisure goods. The racing yachts used

ρC

in the Americas Cup depend almost totally for their high

performance on fiber-reinforced plastics. Using these ma-

terials provides combinations of lightness, strength and

E 1/2

Buckling of — high modulus not available in any other materials. Mod-

ρC

slender column ern tennis rackets used by professionals are usually hollow

or tube molded structures utilizing fiber-reinforced plastic. The

height records that pole vaulters can achieve increased

dramatically with the introduction of the fiber-reinforced

plastic poles. The key property required in this application

E σ y is a high elastic limit. A fiberglass composite has an elastic

Tie

ρC ρC limit of 2–3%, whereas a high strength aluminium alloy is

less than 1%.The high elastic limit of thecomposite means

that it can bend into a radius of about 1 m without breaking,

and in doing so stores enough energy to propel the vaulter

over the bar, which is typically 6 m above the ground.

G σ y

Torsion tube

ρC ρC

C. Medical Applications

Plastics have been a major boon to the medical pro-

E σ y

Cylinder with fession. In North America the value of the industry

ρC ρC

internal pressure has been estimated to be over $4 billion. The pack-

aging of medical products, tubes, and pharmaceutical

closures are routine applications for plastic materials.

Their high impact and chemical resistance and ability

to be easily sterilized make them the first choice in

factors are pushing the increasing use of plastics in cars. many cases. Almost 80% of polymers used in the med-

Not least are the “green” or environmental issues that re- ical industry is represented by PVC, polypropylene, and

quire lighter vehicles (to minimize energy consumption polystyrene. The excellent resistance to steam exposure

and/or facilitate alternative energy sources for the ve- of some plastics (such as polyphenylsulfone) is used very

hicle) as well as the need for recycleability. Many car effectively in special applications such as microfiltration

manufacturers continue to strive for the all-plastic car and devices for immunoassays, reusable syringe injectors,

a number of prototypes have been made and tested by respirators, nebulizers, prosthesis packaging, sterilizer