Page 289 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 289

P1: GPQ Final Pages/GNB P2: GTV

Encyclopedia of Physical Science and Technology En012c-604 July 26, 2001 16:2

798 Polymers, Thermally Stable

semiconductor devices. By “tailoring” properties in the on PI/silica ceramers (polymer–ceramic hybrids). These

ways already described, the major in-built advantages ceramers contain nanoscale silica domains trapped in the

of the PIs—high thermal stability, excellent mechanical PI matrix, the composites exhibiting lower thermal expan-

properties, and low dielectric constant—can be reinforced sion and higher thermal stability compared with carbon

by improved processibility (including highly planar coat- fiber/PI-only composites.

ings), increased adhesion, and low thermal expansion co- Maintaining the thermal/thermo-oxidative stability of

efficient. Recently reported are polypyrrole-PI compos- PIs, while simultaneously increasing their solubility and

ite films which combine high electrical conductivity with processibility, is an ongoing aspect of R&D. The in-

high thermal stability. Two types of film are available: troduction of large bulky units (e.g., the adamantane

Type 1, a polypyrrole-coated PI with maximum conduc- group) pendant to or in-chain continue to feature in

tivity of 10 Scm −1 and Type 2, a PI film loaded with finely breaking up the regular symmetric structure of aromatic

divided polypyrrole particles, producing a maximum con- PIs.

−1

ductivity of 5 × 10 −4 Scm . Both types having a ther- Significant advances in processibility have also been

◦

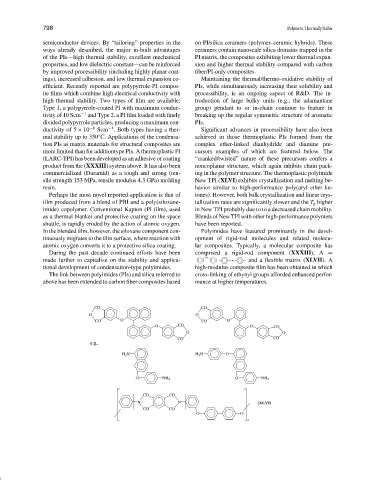

mal stability up to 350 C. Applications of the condensa- achieved in those thermoplastic PIs formed from the

tion PIs as matrix materials for structural composites are complex ether-linked dianhydride and diamine pre-

more limited than for additiontype PIs. A thermoplastic PI cursors examples of which are featured below. The

(LARC-TPI) has been developed as an adhesive or coating “cranked/twisted” nature of these precursors confers a

product from the (XXXIII) system above. It has also been noncoplanar structure, which again inhibits chain pack-

commercialized (Duramid) as a tough and strong (ten- ing in the polymer structure. The thermoplastic polyimide

sile strength 153 MPa, tensile modulus 4.3 GPa) molding New TPI (XLVI) exhibits crystallization and melting be-

resin. havior similar to high-performance poly(aryl ether ke-

Perhaps the most novel reported application is that of tones). However, both bulk crystallization and linear crys-

film produced from a blend of PBI and a poly(siloxane- tallization rates are significantly slower and the T g higher

imide) copolymer. Conventional Kapton (PI film), used in New TPI probably due to to a decreased chain mobility.

as a thermal blanket and protective coating on the space Blends of New TPI with other high-performance polymers

shuttle, is rapidly eroded by the action of atomic oxygen. have been reported.

In the blended film, however, the siloxane component con- Polyimides have featured prominantly in the devel-

tinuously migrates to the film surface, where reaction with opment of rigid-rod molecules and related molecu-

atomic oxygen converts it to a protective silica coating. lar composites. Typically, a molecular composite has

During the past decade continued efforts have been comprised a rigid-rod component (XXXIII), A =

made further to capitalize on the stability and applica- CO CH 2 and a flexible matrix (XLVII). A

tional development of condensation-type polyimides. high-modulus composite film has been obtained in which

The link between polyimides (PIs) and silica referred to cross-linking of ethynyl groups afforded enhanced perfor-

above has been extended to carbon fiber composites based mance at higher temperatures.

CO CO

O O

CO O CO O

O CO O CO

O O

CO CO

e.g.,

H 2 N H 2 N O

O . NH 2 O NH 2

CO CO

N N (XLVI)

CO CO

. O O .

n