Page 233 - Academic Press Encyclopedia of Physical Science and Technology 3rd InOrganic Chemistry

P. 233

P1: GPB Final Pages

Encyclopedia of Physical Science and Technology EN009I-420 July 10, 2001 15:8

380 Mesoporous Materials, Synthesis and Properties

cant catalytic improvement above that of conventional or

commercial catalysts. This is again due to the larger pore

size of mesoporous materials, which allow easy access of

reactants to the active ingredients and subsequent product

release. For transition metal modified mesoporous molec-

ular sieves, innovative applications dealing particularly

with bulky molecules relevant to fine chemical synthesis

are possible. Another important area is the deposition of

transition-metal complexes within the channels and cavi-

ties of mesoporous molecular sieves resulting in materials

that are likely to be useful as enzyme-mimicking catalysts.

B. Thin Films and Membranes—Separation

In order to be used in thin film or membrane applica-

tions, mesoporous materials must be manufactured in the

form of defect-free oriented thin films. These films should

have controllable pore directions as well as variable thick-

ness. Thin films of mesoporus materials can be grown

onto a substrate (e.g., mica) or at the interface between

air and water. A major disadvantage of unidimensional

mesoporous thin films is that their pores tend to be aligned

parallel to the substrate or interface that they are grown

at. In potential applications such as biomolecular separa-

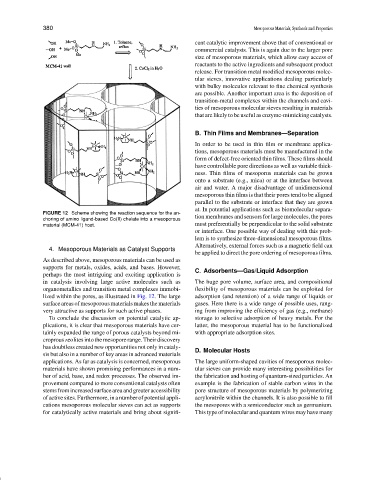

FIGURE 12 Scheme showing the reaction sequence for the an-

choring of amino ligand-based Co(II) chelate into a mesoporous tion membranes and sensors for large molecules, the pores

material (MCM-41) host. must preferentially be perpendicular to the solid substrate

or interface. One possible way of dealing with this prob-

lem is to synthesize three-dimensional mesoporous films.

Alternatively, external forces such as a magnetic field can

4. Mesoporous Materials as Catalyst Supports

be applied to direct the pore ordering of mesoporous films.

As described above, mesoporous materials can be used as

supports for metals, oxides, acids, and bases. However,

C. Adsorbents—Gas/Liquid Adsorption

perhaps the most intriguing and exciting application is

in catalysis involving large active molecules such as The huge pore volume, surface area, and compositional

organometallics and transition metal complexes immobi- flexibility of mesoporous materials can be exploited for

lized within the pores, as illustrated in Fig. 12. The large adsorption (and retention) of a wide range of liquids or

surface areas of mesoporous materials makes the materials gases. Here there is a wide range of possible uses, rang-

very attractive as supports for such active phases. ing from improving the efficiency of gas (e.g., methane)

To conclude the discussion on potential catalytic ap- storage to selective adsorption of heavy metals. For the

plications, it is clear that mesoporous materials have cer- latter, the mesoporous material has to be functionalized

tainly expanded the range of porous catalysts beyond mi- with appropriate adsorption sites.

croprous zeolites into the mesopore range. Their discovery

has doubtless created new opportunities not only in cataly- D. Molecular Hosts

sis but also in a number of key areas in advanced materials

applications. As far as catalysis is concerned, mesoporous The large uniform-shaped cavities of mesoporous molec-

materials have shown promising performances in a num- ular sieves can provide many interesting possibilities for

ber of acid, base, and redox processes. The observed im- the fabrication and hosting of quantum-sized particles. An

provement compared to more conventional catalysts often example is the fabrication of stable carbon wires in the

stems from increased surface area and greater accessibility pore structure of mesoporous materials by polymerizing

of active sites. Furthermore, in a number of potential appli- acrylonitrile within the channels. It is also possible to fill

cations mesoporous molecular sieves can act as supports the mesopores with a semiconductor such as germanium.

for catalytically active materials and bring about signifi- This type of molecular and quantum wires may have many