Page 165 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 165

Cracking of Toxic Waste 145

and nitrogen through the use of additional chlorine or sodium hypochlorite,

but at a lower pH level than that used in the first treatment stage.

First Stage

The following equation illustrates the chemical breakdown of cyanide to

cyanate:

NaCN + 2NaOH Cl ↔ NaCNOH O

+

+

2

2

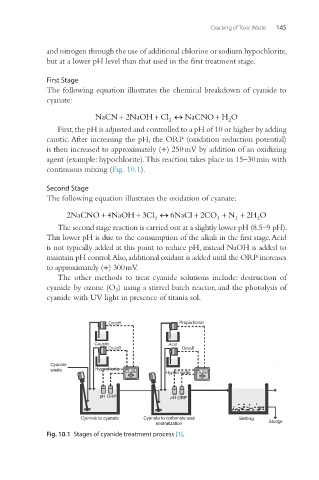

First, the pH is adjusted and controlled to a pH of 10 or higher by adding

caustic. After increasing the pH, the ORP (oxidation reduction potential)

is then increased to approximately (+) 250 mV by addition of an oxidizing

agent (example: hypochlorite). This reaction takes place in 15–30 min with

continuous mixing (Fig. 10.1).

Second Stage

The following equation illustrates the oxidation of cyanate:

2NaCNO4NaOH 3Cl ↔ 6NaCl + 2CO + N + 2H O

+

+

2

2

2

2

The second stage reaction is carried out at a slightly lower pH (8.5–9 pH).

This lower pH is due to the consumption of the alkali in the first stage. Acid

is not typically added at this point to reduce pH, instead NaOH is added to

maintain pH control. Also, additional oxidant is added until the ORP increases

to approximately (+) 300 mV.

The other methods to treat cyanide solutions include: destruction of

cyanide by ozone (O 3 ) using a stirred batch reactor, and the photolysis of

cyanide with UV light in presence of titania sol.

On/off Proportional

Caustic Acid

On/off On/off

Cyanide

waste Hypochlorite 5.00 Hypochlorite 5.00

pH ORP pH ORP

Cyanide to cyanate Cyanate to carbonate and Settling

neutralization Sludge

Fig. 10.1 Stages of cyanide treatment process [1].