Page 49 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 49

Energy Extraction From Toxic Waste Originating From Food Processing Industries 37

place when the biomass burns (i.e., flaming mode) or when it is exposed to

elevated temperatures without burning (i.e., nonflaming mode). All com-

bustible materials, whether synthetic or man-made, generally produce toxic

products when burned. When biomass is heated under oxygen-deficient

conditions, it generates syngas, which consists primarily of hydrogen (H 2 )

and carbon monoxide (CO). This syngas can be directly burnt or further

processed for gaseous or liquid products, such as producer gas and pyro oil.

Low moisture content biomasses are more suitable for conversion processes

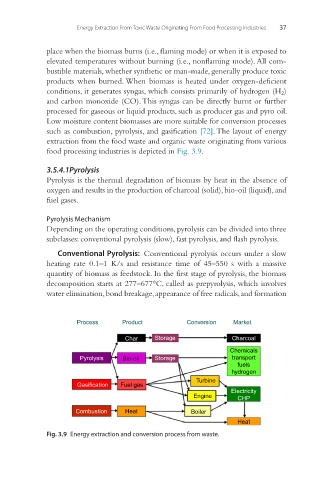

such as combustion, pyrolysis, and gasification [72]. The layout of energy

extraction from the food waste and organic waste originating from various

food processing industries is depicted in Fig. 3.9.

3.5.4.1Pyrolysis

Pyrolysis is the thermal degradation of biomass by heat in the absence of

oxygen and results in the production of charcoal (solid), bio-oil (liquid), and

fuel gases.

Pyrolysis Mechanism

Depending on the operating conditions, pyrolysis can be divided into three

subclasses: conventional pyrolysis (slow), fast pyrolysis, and flash pyrolysis.

Conventional Pyrolysis: Conventional pyrolysis occurs under a slow

heating rate 0.1–1 K/s and resistance time of 45–550 s with a massive

quantity of biomass as feedstock. In the first stage of pyrolysis, the biomass

decomposition starts at 277–677°C, called as prepyrolysis, which involves

water elimination, bond breakage, appearance of free radicals, and formation

Process Product Conversion Market

Char Storage Charcoal

Chemicals

Pyrolysis Bio-oil Storage transport

fuels

hydrogen

Turbine

Gasification Fuel gas

Electricity

Engine CHP

Combustion Heat Boiler

Heat

Fig. 3.9 Energy extraction and conversion process from waste.