Page 127 - Engineered Interfaces in Fiber Reinforced Composites

P. 127

110 Engineered interfaces in fiber reinforced composites

related to a single parameter such as the interface bond strength, zb, as in

conventional analyses of the test given by Eq. (3.3).

4.2.4. An improved model based on a shear strength criterion

Although a fracture mechanics approach presented in Section 4.2.3 in general

deals with a more fundamental aspect of the interface debond problem for a given

loading configuration, a shear strength criterion has an important advantage in that

the interfacial shear strength, whether for the bonded or debonded regions, can be

directly determined from the experimental results of the fiber fragmentation test.

Therefore, in this section, a micromechanics analysis is presented based on the shear

strength criterion for interfacial debonding. A particular emphasis is placed on the

identification of the specific criteria required to satisfy each interface condition, i.e.

full bonding, partial debonding and full frictional bonding. The approximate

analysis given in this model leads to relatively simple, closed-form equations for all

basic solutions for the stress distributions in the constituents, the external stress

required for debonding or fiber fragmentation, and the mean fiber fragmentation

length for the three different interface conditions.

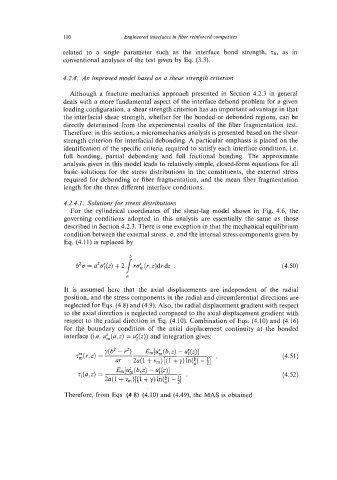

4.2.4.1. Solutions for stress distributions

For the cylindrical coordinates of the shear-lag model shown in Fig. 4.6, the

governing conditions adopted in this analysis are essentially the same as those

described in Section 4.2.3. There is one exception in that the mechanical equilibrium

condition between the external stress, 0, and the internal stress components given by

Eq. (4.11) is replaced by

b

b20 = a2+) +2/r8m(r,z)drdz (4.50)

a

It is assumed here that the axial displacements are independent of the radial

position, and the stress components in the radial and circumferential directions are

neglected for Eqs. (4.8) and (4.9). Also, the radial displacement gradient with respect

to the axial direction is neglected compared to the axial displacement gradient with

respect to the radial direction in Eq. (4.10). Combination of Eqs. (4.10) and (4.16)

for the boundary condition of the axial displacement continuity at the bonded

interface &e. u‘m(a,z) = U;(z)) and integration gives:

(4.51)

(4.52)

Therefore, from Eqs (4 8) (4.10) and (4.49), the MAS is obtained