Page 206 - Engineered Interfaces in Fiber Reinforced Composites

P. 206

188 Engineered interfaces in jiber reinforced composites

Power supply

1

Matching unit

I

4

~

1 Plasma

f I I

Fiber Fiber

supply take-up

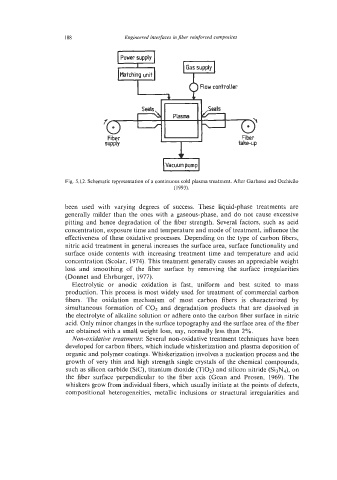

Fig. 5.12. Schematic representation of a continuous cold plasma treatment. After Garbassi and Occhiello

(1993).

been used with varying degrees of success. These liquid-phase treatments are

generally milder than the ones with a gaseous-phase, and do not cause excessive

pitting and hence degradation of the fiber strength. Several factors, such as acid

concentration, exposure time and temperature and mode of treatment, influence the

effectiveness of these oxidative processes. Depending on the type of carbon fibers,

nitric acid treatment in general increases the surface area, surface functionality and

surface oxide contents with increasing treatment time and temperature and acid

concentration (Scolar, 1974). This treatment generally causes an appreciable weight

loss and smoothing of the fiber surface by removing the surface irregularities

(Donnet and Ehrburger, 1977).

Electrolytic or anodic oxidation is fast, uniform and best suited to mass

production. This process is most widely used for treatment of commercial carbon

fibers. The oxidation mechanism of most carbon fibers is characterized by

simultaneous formation of C02 and degradation products that are dissolved in

the electrolyte of alkaline solution or adhere onto the carbon fiber surface in nitric

acid. Only minor changes in the surface topography and the surface area of the fiber

are obtained with a small weight loss, say, normally less than 2%.

Non-oxidative treatments: Several non-oxidative treatment techniques have been

developed for carbon fibers, which include whiskerization and plasma deposition of

organic and polymer coatings. Whiskerization involves a nucleation process and the

growth of very thin and high strength single crystals of the chemical compounds,

such as silicon carbide (Sic), titanium dioxide (TiOz) and silicon nitride (Si3N4), on

the fiber surface perpendicular to the fiber axis (Goan and Prosen, 1969). The

whiskers grow from individual fibers, which usually initiate at the points of defects,

compositional heterogeneities, metallic inclusions or structural irregularities and