Page 220 - Engineered Interfaces in Fiber Reinforced Composites

P. 220

202 Engineered interfaces in jiber reinforced composites

. .

. _... .

, .._

1

-100nm fibrils

-10nm microfibrils

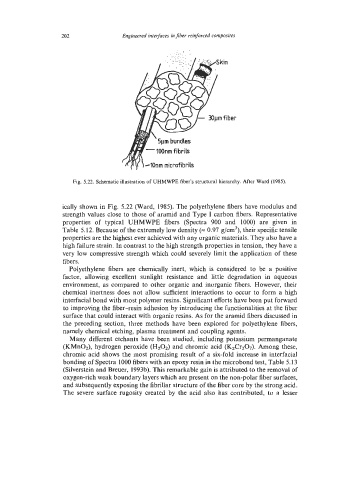

Fig. 5.22. Schematic illustration of UHMWPE fiber’s structural hierarchy. After Ward (1985).

ically shown in Fig. 5.22 (Ward, 1985). The polyethylene fibers have modulus and

strength values close to those of aramid and Type I carbon fibers. Representative

properties of typical UHMWPE fibers (Spectra 900 and 1000) are given in

Table 5.12. Because of the extremely low density (= 0.97 g/cm3), their specific tensile

properties are the highest ever achieved with any organic materials. They also have a

high failure strain. In contrast to the high strength properties in tension, they have a

very low compressive strength which could severely limit the application of these

fibers.

Polyethylene fibers are chemically inert, which is considered to be a positive

factor, allowing excellent sunlight resistance and little degradation in aqueous

environment, as compared to other organic and inorganic fibers. However, their

chemical inertness does not allow sufficient interactions to occur to form a high

interfacial bond with most polymer resins. Significant efforts have been put forward

to improving the fiber-resin adhesion by introducing the functionalities at the fiber

surface that could interact with organic resins. As for the aramid fibers discussed in

the preceding section, three methods have been explored for polyethylene fibers,

namely chemical etching, plasma treatment and coupling agents.

Many different etchants have been studied, including potassium permanganate

(KMn02), hydrogen peroxide (H202) and chromic acid (K2Cr207). Among these,

chromic acid shows the most promising result of a six-fold increase in interfacial

bonding of Spectra 1000 fibers with an epoxy resin in the microbond test, Table 5.13

(Silverstein and Breuer, 1993b). This remarkable gain is attributed to the removal of

oxygen-rich weak boundary layers which are present on the non-polar fiber surfaces,

and subsequently exposing the fibrillar structure of the fiber core by the strong acid.

The severe surface rugosity created by the acid also has contributed, to a lesser