Page 241 - Engineered Interfaces in Fiber Reinforced Composites

P. 241

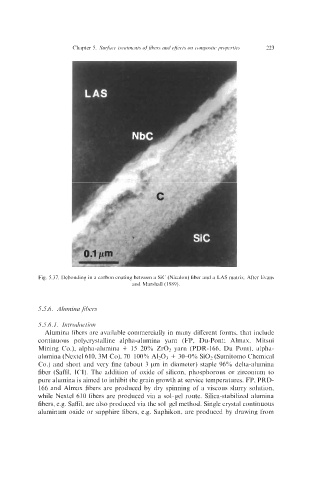

Fig. 5.37. Debonding in a carbon coating between a Sic (Nicalon) fiber and a LAS matrix. After Evans

and Marshall (1 989).

5.5.6. Alutninci ,fibers

5.5.6.1. Ititroc/irctioti

Alumina fibers are available commercially in many different forms, that include

continuous polycrystalline alpha-alumina yarn (FP, Du-Pont; Almax, Mitsui

Mining Co.), alpha-alumina + 15-20% ZrOz yarn (PDR-166, Du Pont), alpha-

alumina (Nextel 610, 3M Co), 70-100% A1203 + 3(M% Si02 (Sumitomo Chemical

Co.) and short and very fine (about 3 pm in diameter) staple 96% delta-alumina

fiber (Saffil, ICI). The addition of oxide of silicon, phosphorous or zirconium to

pure alumina is aimed to inhibit the grain growth at service temperatures. FP, PRD-

166 and Almax fibers are produced by dry spinning of a viscous slurry solution,

while Nextel 610 fibers are produced via a sol-gel route. Silica-stabilized alumina

fibers, e.g. Saffil, are also produced via the sol-gel method. Single crystal continuous

aluminum oxide or sapphire fibers, e.g. Saphikon, are produced by drawing from