Page 246 - Engineered Interfaces in Fiber Reinforced Composites

P. 246

Chapter 5. Surfuce treatments qf,fibers and effects on composite properties 227

at the fiber-Sn02 interface is purely mechanical, whereas that between SnO2 and

glass is a combination of chemical and mechanical bonds. Fig. 5.39 shows a

characteristic planar brittle fracture and pull-out fibers in uncoated and Sn02 coated

PRD- 166 fiber-glass matrix composites, respectively. The major toughening

mechanisms in the coated fiber composite are mainly crack bridging and crack

deflection (Chawla, 1993). The beneficial effects of Sn02 coating on A1203 fiber has

also been demonstrated in flexure and compression tests (Siadati et al., 1991).

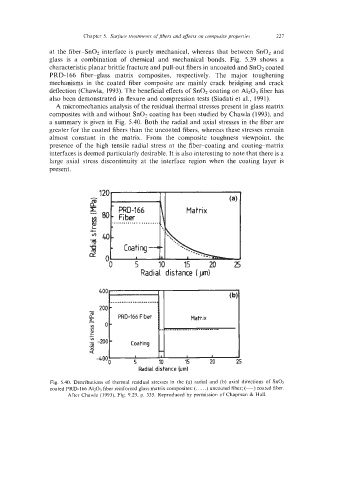

A rnicromechanics analysis of the residual thermal stresses present in glass matrix

composites with and without Sn02 coating has been studied by Chawla (1993), and

a summary is given in Fig. 5.40. Both the radial and axial stresses in the fiber are

greater for the coated fibers than the uncoated fibers, whereas these stresses remain

almost constant in the matrix. From the composite toughness viewpoint, the

presence of the high tensile radial stress at the fiber-coating and coating-matrix

interfaces is deemed particularly desirable. It is also interesting to note that there is a

large axial stress discontinuity at the interface region when the coating layer is

present.

I

Radial distance (p)

400 (bl

-

.........................

200

ID

a PRD-166 Fiber Matrix

E

3 0- ................................

2

c

.- Coating

v1

- -200-

m

X

a -

1 I I I

5

Radial distance @rn)

Fig. 5.40. Distributions of thermal residual stresses in the (a) radial and (b) axial directions of SnOz

coated PRD-166 Al2O3 fiber reinforced glass matrix composites: (. ... .) uncoated fiber; (-) coated fiber.

After Chawla (1993), Fig. 9.29, p. 335. Reproduced by permission of Chapman & Hall.