Page 195 - Engineering Plastics Handbook

P. 195

168 Engineering Plastics

TABLE 8.3 Comparative Properties for BPADA-MPD PEI Resin at Various Levels of

Glass Reinforcement

10% Fiber- 20% Fiber- 30% Fiber- 40% Fiber-

Properties glass glass glass glass

HDT at 0.5 MPa 223 (434) 226 (438) 228 (442) 234 (454)

(66 psi ), °C (°F)

HDT at 1.9 MPa 207 (405) 209 (408) 212 (414) 208 (406)

(264 psi), °C (°F)

T g ,°C (°F) 217 (425) 217 (425) 217 (425) 217 (425)

Tensile stress Y, MPa (kpsi) 114 (16.6) 139 (20.1) 169 (24.5) 186 (27.0)

Tensile modulus, MPa (kpsi) 4482 (650) 6895 (1000) 8963 (1300) 11,721 (1700)

% Elongation 4.5 3.0 3.0 2.5

Flexural modulus, MPa (kpsi) 4482 (650) 6205 (900) 8963 (1300) 11,721 (1700)

Flexural stress, MPa (kpsi) 193 (28.0) 207 (30.0) 228 (33.0) 248 (36.0)

N. Izod, J/m (ft⋅lb/in) 59 (1.1) 91 (1.7) 107 (2.0) 107 (2.0)

% Ash 10 20 30 40

Specific gravity 1.34 1.42 1.51 1.61

Other forms of glass commonly used in PEI resin include chopped

fiber, milled glass, glass beads, and glass flake. Glass fibers provide the

best stiffness and strength (with longer fibers providing higher values

but more orientation effects). Shorter-aspect-ratio glass fillers (e.g.,

milled glass and glass bead) produce parts with more isometric prop-

erties. Said another way, these lower-aspect-ratio fillers produce less

anisotropy (less orientation of the filler) in the final molded part.

PEI resins can also be blended with numerous mineral fillers such as

talc, clay, wollastonite, titanium dioxide, barite, and mica. In general,

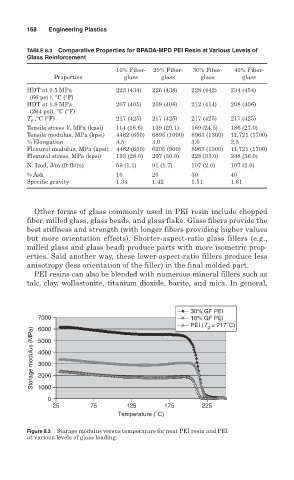

30% GF PEI

7000 10% GF PEI

PEI (T = 217°C)

g

Storage modulus (MPa) 4000

6000

5000

3000

2000

1000

0

25 75 125 175 225

Temperature (°C)

Figure 8.3 Storage modulus versus temperature for neat PEI resin and PEI

at various levels of glass loading.