Page 192 - Engineering Plastics Handbook

P. 192

Thermoplastic Polyetherimide (PEI) 165

3000

PEI (T g = 217°C)

Storage modulus (MPa) 2000 PEEK (T g = 150°C)

PEIS (T = 248°C)

g

1000

0

50 100 150 200 250 300

Temperature (°C)

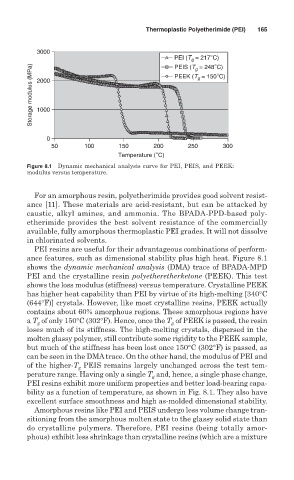

Figure 8.1 Dynamic mechanical analysis curve for PEI, PEIS, and PEEK:

modulus versus temperature.

For an amorphous resin, polyetherimide provides good solvent resist-

ance [11]. These materials are acid-resistant, but can be attacked by

caustic, alkyl amines, and ammonia. The BPADA-PPD-based poly-

etherimide provides the best solvent resistance of the commercially

available, fully amorphous thermoplastic PEI grades. It will not dissolve

in chlorinated solvents.

PEI resins are useful for their advantageous combinations of perform-

ance features, such as dimensional stability plus high heat. Figure 8.1

shows the dynamic mechanical analysis (DMA) trace of BPADA-MPD

PEI and the crystalline resin polyetheretherketone (PEEK). This test

shows the loss modulus (stiffness) versus temperature. Crystalline PEEK

has higher heat capability than PEI by virtue of its high-melting [340°C

(644°F)] crystals. However, like most crystalline resins, PEEK actually

contains about 60% amorphous regions. These amorphous regions have

a T of only 150°C (302°F). Hence, once the T of PEEK is passed, the resin

g

g

loses much of its stiffness. The high-melting crystals, dispersed in the

molten glassy polymer, still contribute some rigidity to the PEEK sample,

but much of the stiffness has been lost once 150°C (302°F) is passed, as

can be seen in the DMAtrace. On the other hand, the modulus of PEI and

of the higher-T PEIS remains largely unchanged across the test tem-

g

perature range. Having only a single T and, hence, a single phase change,

g

PEI resins exhibit more uniform properties and better load-bearing capa-

bility as a function of temperature, as shown in Fig. 8.1. They also have

excellent surface smoothness and high as-molded dimensional stability.

Amorphous resins like PEI and PEIS undergo less volume change tran-

sitioning from the amorphous molten state to the glassy solid state than

do crystalline polymers. Therefore, PEI resins (being totally amor-

phous) exhibit less shrinkage than crystalline resins (which are a mixture