Page 196 - Engineering Plastics Handbook

P. 196

Thermoplastic Polyetherimide (PEI) 169

1.00

40% HF fiberglass flow

0.75

Aluminum

0.50

% Expansion 0.25

0.00

−0.25

−0.50

−70 −20 30 80 130 180

Temperature (°C)

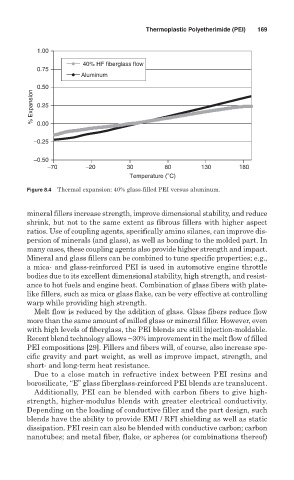

Figure 8.4 Thermal expansion: 40% glass-filled PEI versus aluminum.

mineral fillers increase strength, improve dimensional stability, and reduce

shrink, but not to the same extent as fibrous fillers with higher aspect

ratios. Use of coupling agents, specifically amino silanes, can improve dis-

persion of minerals (and glass), as well as bonding to the molded part. In

many cases, these coupling agents also provide higher strength and impact.

Mineral and glass fillers can be combined to tune specific properties; e.g.,

a mica- and glass-reinforced PEI is used in automotive engine throttle

bodies due to its excellent dimensional stability, high strength, and resist-

ance to hot fuels and engine heat. Combination of glass fibers with plate-

like fillers, such as mica or glass flake, can be very effective at controlling

warp while providing high strength.

Melt flow is reduced by the addition of glass. Glass fibers reduce flow

more than the same amount of milled glass or mineral filler. However, even

with high levels of fiberglass, the PEI blends are still injection-moldable.

Recent blend technology allows ~30% improvement in the melt flow of filled

PEI compositions [29]. Fillers and fibers will, of course, also increase spe-

cific gravity and part weight, as well as improve impact, strength, and

short- and long-term heat resistance.

Due to a close match in refractive index between PEI resins and

borosilicate, “E” glass fiberglass-reinforced PEI blends are translucent.

Additionally, PEI can be blended with carbon fibers to give high-

strength, higher-modulus blends with greater electrical conductivity.

Depending on the loading of conductive filler and the part design, such

blends have the ability to provide EMI / RFI shielding as well as static

dissipation. PEI resin can also be blended with conductive carbon; carbon

nanotubes; and metal fiber, flake, or spheres (or combinations thereof)