Page 187 - Engineering Plastics Handbook

P. 187

160 Engineering Plastics

It is common practice to combine two polymers with the same over-

all chemical structure, but differing molecular weights, to control the

melt viscosity of the resultant resin. This can be accomplished in sev-

eral different ways, e.g., by blending pellets and melt-mixing in an

extruder or molding machine.

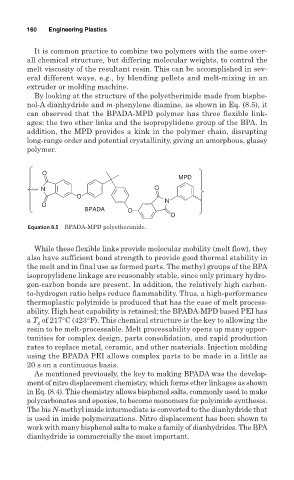

By looking at the structure of the polyetherimide made from bisphe-

nol-A dianhydride and m-phenylene diamine, as shown in Eq. (8.5), it

can observed that the BPADA-MPD polymer has three flexible link-

ages: the two ether links and the isopropylidene group of the BPA. In

addition, the MPD provides a kink in the polymer chain, disrupting

long-range order and potential crystallinity, giving an amorphous, glassy

polymer.

O

MPD

N O

O

N

O

BPADA O

O

Equation 8.5 BPADA-MPD polyetherimide.

While these flexible links provide molecular mobility (melt flow), they

also have sufficient bond strength to provide good thermal stability in

the melt and in final use as formed parts. The methyl groups of the BPA

isopropylidene linkage are reasonably stable, since only primary hydro-

gen-carbon bonds are present. In addition, the relatively high carbon-

to-hydrogen ratio helps reduce flammability. Thus, a high-performance

thermoplastic polyimide is produced that has the ease of melt process-

ability. High heat capability is retained; the BPADA-MPD based PEI has

a T of 217°C (423°F). This chemical structure is the key to allowing the

g

resin to be melt-processable. Melt processability opens up many oppor-

tunities for complex design, parts consolidation, and rapid production

rates to replace metal, ceramic, and other materials. Injection molding

using the BPADA PEI allows complex parts to be made in a little as

20 s on a continuous basis.

As mentioned previously, the key to making BPADA was the develop-

ment of nitro displacement chemistry, which forms ether linkages as shown

in Eq. (8.4). This chemistry allows bisphenol salts, commonly used to make

polycarbonates and epoxies, to become monomers for polyimide synthesis.

The bis N-methyl imide intermediate is converted to the dianhydride that

is used in imide polymerizations. Nitro displacement has been shown to

work with many bisphenol salts to make a family of dianhydrides. The BPA

dianhydride is commercially the most important.