Page 184 - Engineering Plastics Handbook

P. 184

Thermoplastic Polyetherimide (PEI) 157

solution, or a solution that is only partially imidized, is used to make a film,

laminate, or other shapes. The polyamide acid is then heated during (or

after) the forming process to remove solvent and water to form the final poly-

imide. This complicates the forming process, which requires a chemical reac-

tion, the elimination of water, in addition to removal of solvent. These

additional requirements can be accommodated in simple operations, e.g.,

casting thin film, where a high surface area is present to aid in solvent and

water removal. However, making more complex shapes is difficult.

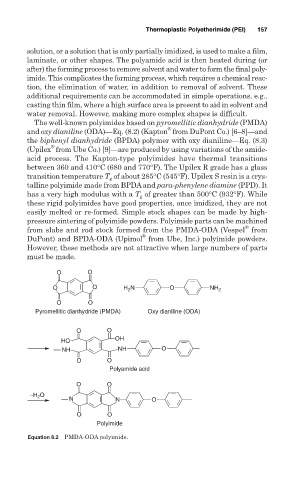

The well-known polyimides based on pyromellitic dianhydride (PMDA)

®

and oxy dianiline (ODA)—Eq. (8.2) (Kapton from DuPont Co.) [6–8]—and

the biphenyl dianhydride (BPDA) polymer with oxy dianiline—Eq. (8.3)

®

(Upilex from Ube Co.) [9]—are produced by using variations of the amide-

acid process. The Kapton-type polyimides have thermal transitions

between 360 and 410°C (680 and 770°F). The Upilex R grade has a glass

transition temperature T of about 285°C (545°F). Upilex S resin is a crys-

g

talline polyimide made from BPDAand para-phenylene diamine (PPD). It

has a very high modulus with a T of greater than 500°C (932°F). While

g

these rigid polyimides have good properties, once imidized, they are not

easily melted or re-formed. Simple stock shapes can be made by high-

pressure sintering of polyimide powders. Polyimide parts can be machined

®

from slabs and rod stock formed from the PMDA-ODA (Vespel from

®

DuPont) and BPDA-ODA (Upimol from Ube, Inc.) polyimide powders.

However, these methods are not attractive when large numbers of parts

must be made.

O O

O O H N O NH 2

2

O O

Pyromellitic dianhydride (PMDA) Oxy dianiline (ODA)

O O

OH

HO

NH NH O

O O

Polyamide acid

O O

−H O N N O

2

O O

Polyimide

Equation 8.2 PMDA-ODA polyimide.