Page 189 - Engineering Plastics Handbook

P. 189

162 Engineering Plastics

O

PPD

O

N

O

N

O

O

BPADA O

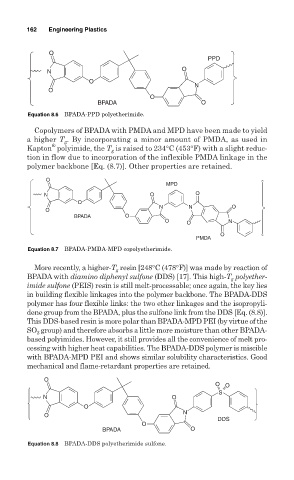

Equation 8.6 BPADA-PPD polyetherimide.

Copolymers of BPADA with PMDA and MPD have been made to yield

a higher T . By incorporating a minor amount of PMDA, as used in

g

®

Kapton polyimide, the T is raised to 234°C (453°F) with a slight reduc-

g

tion in flow due to incorporation of the inflexible PMDA linkage in the

polymer backbone [Eq. (8.7)]. Other properties are retained.

O

MPD

N O O

O

N N O

O

BPADA O

O O N

O

PMDA

Equation 8.7 BPADA-PMDA-MPD copolyetherimide.

More recently, a higher-T resin [248°C (478°F)] was made by reaction of

g

BPADA with diamino diphenyl sulfone (DDS) [17]. This high-T polyether-

g

imide sulfone (PEIS) resin is still melt-processable; once again, the key lies

in building flexible linkages into the polymer backbone. The BPADA-DDS

polymer has four flexible links: the two ether linkages and the isopropyli-

dene group from the BPADA, plus the sulfone link from the DDS [Eq. (8.8)].

This DDS-based resin is more polar than BPADA-MPD PEI (by virtue of the

group) and therefore absorbs a little more moisture than other BPADA-

SO 2

based polyimides. However, it still provides all the convenience of melt pro-

cessing with higher heat capabilities. The BPADA-DDS polymer is miscible

with BPADA-MPD PEI and shows similar solubility characteristics. Good

mechanical and flame-retardant properties are retained.

O

O O

S

N O

O

N

O

DDS

O

BPADA O

Equation 8.8 BPADA-DDS polyetherimide sulfone.