Page 215 - Engineering Plastics Handbook

P. 215

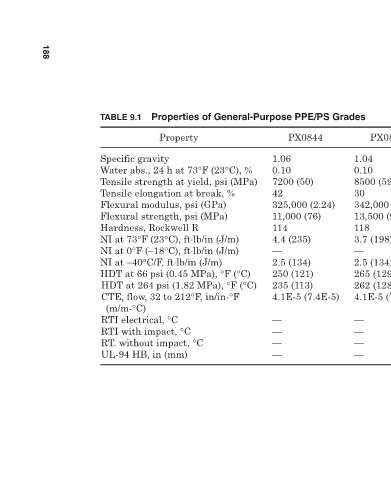

PX0888 STN15HF PX1391 PX1265 1.04 1.07 1.06 0.2 0.10 0.10 6700 (46) 10,000 (69) 9000 (62) 70 25 35 290,000 (2.00) 355,000 (2.45) 335,000 (2.31) 342,000 (2.36) 10,100 (70) 16,000 (110) 13,500 (93) 13,500 (93) — — — 8.5 (454) 4.2 (224) 4.6 (246) 4.7 (251) — — 4.2 (224) 2.

1.04 0.10 8500 (59) 30 118 3.7 (198) — 2.5 (134) 265 (129) 262 (128) — — — —

Properties of General-Purpose PPE/PS Grades

PX0844 325,000 (2.24) 11,000 (76) 4.1E-5 (7.4E-5)

1.06 0.10 7200 (50) 42 114 4.4 (235) — 2.5 (134) 250 (121) 235 (113) — — — —

Property Water abs., 24 h at 73°F (23°C), % Tensile strength at yield, psi (MPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) NI at 73°F (23°C), ft⋅lb/in (J/m) NI at 0°F (−18°C), ft⋅lb/in (J/m) NI at −40°C/F, ft⋅lb/in (J/m) HDT at 66 psi (0.45 MPa

TABLE 9.1 Specific gravity Hardness, Rockwell R (m/m-°C) RTI electrical, °C RTI with impact, °C UL-94 HB, in (mm)

188