Page 220 - Engineering Plastics Handbook

P. 220

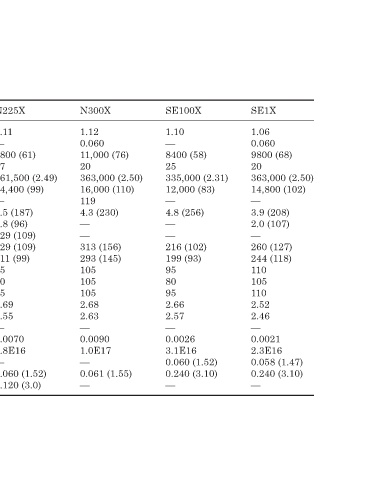

SE1X 1.06 0.060 9800 (68) 20 363,000 (2.50) 14,800 (102) — 3.9 (208) 2.0 (107) — 260 (127) 244 (118) 110 105 110 2.52 2.46 — 0.0021 2.3E16 0.058 (1.47) 0.240 (3.10) —

SE100X 1.10 — 8400 (58) 25 335,000 (2.31) 12,000 (83) — 4.8 (256) — — 216 (102) 199 (93) 95 80 95 2.66 2.57 — 0.0026 3.1E16 0.060 (1.52) 0.240 (3.10) —

N300X 1.12 0.060 11,000 (76) 20 363,000 (2.50) 16,000 (110) 119 4.3 (230) — — 313 (156) 293 (145) 105 105 105 2.68 2.63 — 0.0090 1.0E17 — 0.061 (1.55) —

N225X 1.11 — 8800 (61) 17 361,500 (2.49) 14,400 (99) — 3.5 (187) 1.8 (96) 229 (109) 229 (109) 211 (99) 95 80 95 2.69 2.55 — 0.0070 2.8E16 — 0.060 (1.52) 0.120 (3.0)

Properties of Flame-Retardant PPE/PS Grades

N190X 1.12 0.080 8000 (55) 18 332,200 (2.29) 13,250 (91) 120 5.5 (294) 1.2 (64) 235 (113) 205 (96) 190 (88) 95 80 95 2.74 — 0.0130 — 1.8E16 — 0.058 (1.47) 0.120 (3.0)

Property Water abs., 24 h at 73°F (23°C), % Tensile strength at yield, psi (MPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) Notched Izod at 23°C, ft⋅lb/in (J/m) Notched Izod at −22°F, ft⋅lb/in (J/m) Vicat softening temp., rate B, °F (°C) HDT at 66 ps

TABLE 9.3 Specific gravity Hardness, Rockwell R Dielectric constant, 60 Hz Dielectric constant, 1 MHz Dissipation factor, 60 Hz Dissipation factor, 1 MHz Volume resistivity, Ω⋅cm

191