Page 225 - Engineering Plastics Handbook

P. 225

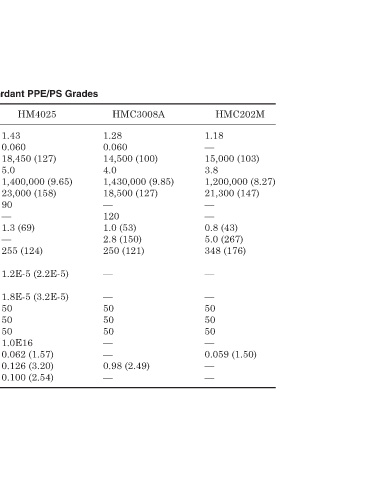

HMC202M 15,000 (103) 1,200,000 (8.27) 21,300 (147) 0.059 (1.50)

1.18 — 3.8 — — 0.8 (43) 5.0 (267) 348 (176) — — 50 50 50 — — —

HMC3008A 1.28 0.060 14,500 (100) 4.0 1,430,000 (9.85) 18,500 (127) — 120 1.0 (53) 2.8 (150) 250 (121) — — 50 50 50 — — 0.98 (2.49) —

Properties of High-Modulus, Reinforced Flame-Retardant PPE/PS Grades

HM4025 18,450 (127) 1,400,000 (9.65) 23,000 (158) 1.2E-5 (2.2E-5) 1.8E-5 (3.2E-5) 0.062 (1.57) 0.126 (3.20) 0.100 (2.54)

1.43 0.060 5.0 90 — 1.3 (69) — 255 (124) 50 50 50 1.0E16

HM3020 15,000 (107) 1,100,000 (7.58) 21,000 (1450) 1.3E-5 (2.3E-5) 1.9E-5 (3.4E-5) 0.058 (1.47) 0.101 (2.57)

1.31 0.060 — 88 — 1.7 (91) — 248 (120) 50 50 50 1.0E16 —

Property Water abs., 24 h at 73°F (23°C), % Tensile strength at yield, psi (MPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) NI at 23°C, ft⋅lb/in (J/m) UNI at 23°C, ft⋅lb/in (J/m) HDT at 264 psi (1.82 MPa),°F (°C) CTE, flow −40° to 200°F, in/in-°F CT

TABLE 9.5 Specific gravity Hardness, Rockwell M Hardness, Rockwell R (m/m-°C) (m/m-°C) RTI electrical, °C RTI with impact, °C UL-94 V-1, in (mm) UL-94 V-0, in (mm) UL-94-5 VA, in (mm)

194