Page 222 - Engineering Plastics Handbook

P. 222

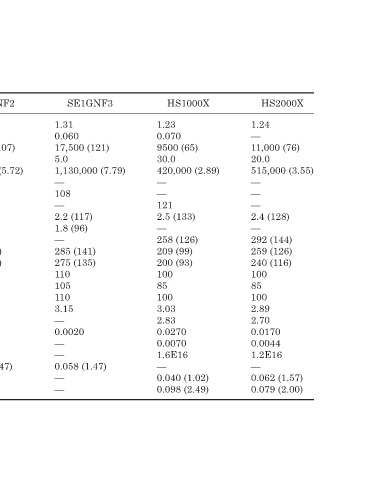

HS2000X 11,000 (76) 515,000 (3.55) 292 (144) 259 (126) 240 (116) 0.062 (1.57) 0.079 (2.00)

1.24 — 20.0 — — — 2.4 (128) — 100 85 100 2.89 2.70 0.0170 0.0044 1.2E16 —

HS1000X 9500 (65) 420,000 (2.89) 2.5 (133) 258 (126) 0.040 (1.02) 0.098 (2.49)

1.23 0.070 30.0 — — 121 — 209 (99) 200 (93) 100 85 100 3.03 2.83 0.0270 0.0070 1.6E16 —

SE1GNF3 17,500 (121) 1,130,000 (7.79) 0.058 (1.47)

1.31 0.060 5.0 — 108 — 2.2 (117) 1.8 (96) — 285 (141) 275 (135) 110 105 110 3.15 — 0.0020 — — — —

SE1GNF2 1.23 0.060 15,500 (107) 5.0 830,000 (5.72) — 106 — 2.0 (107) 1.8 (96) — 280 (138) 270 (132) 110 105 110 2.98 — 0.0016 — — 0.058 (1.47) — —

Properties of Reinforced, Flame-Retardant Grades

SE1GNF1 1.16 0.070 10,800 (74) 5.0 580,000 (4.00) 17,400 (120) 104 — 1.8 (96) 1.3 (69) 298 (148) — 269 (132) 110 105 110 3.00 3.00 0.0017 0.0016 1.0E15 0.058 (1.47) — —

Property Water abs., 24 h at 73°F (23°C), % Tensile strength at yield, psi (MPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) NI at 23°C, ft⋅lb/in (J/m) NI at −40°C/F, ft⋅lb/in (J/m) HDT at 66 psi (0.45 MPa), °F (°C) HDT at 264 psi (1.82 MPa), °F (°C)

TABLE 9.4 Specific gravity Hardness, Rockwell L Hardness, Rockwell R Vicat B, °F (°C) RTI electrical, °C RTI with impact, °C UL-94 V, in (mm) UL-94 V-0, in (mm) UL-94-5 VA, in (mm)

192