Page 217 - Engineering Plastics Handbook

P. 217

Polyphenylene Ether (PPE) Blends and Alloys 189

PX1265: 276°F (136°C) HDT at 264 psi (1.82 MPa)

PX1391: 309°F (154°C) HDT at 264 psi (1.82 MPa); high heat resistance

STN15HF: 240°F (116°C) HDT at 264 psi (1.82 MPa); high impact

Glass-reinforced (general-purpose) grades. These offer a combination of

high strength, stiffness, modulus, and dimensional stability. The heat per-

formance and low specific gravity of modified PPE reinforced resins pro-

vide many value options versus other engineering thermoplastic resins and

versus traditional materials such as brass, aluminum, and other metals.

Applications for reinforced modified PPE resins include pump housings,

impellers and components, structural parts such as motor mounts, frames

and brackets, water filters, coils, and bobbins for automotive ignitions.

Representative properties of glass-reinforced PPE/PS grades appear in

Table 9.2. Glass-reinforced grades and key features include

Noryl GFN1: 10% glass-reinforced, 256°F (120°C) HDT at 264 psi

(1.82 MPa); FDAcompliant, NSF Standard 61 listed (restrictions apply)

Noryl GFN2: 20% glass-reinforced, 280°F (138°C) HDT at 264 psi

(1.82 MPa); FDAcompliant, NSF Standard 61 listed (restrictions apply)

Noryl GFN3: 30% glass-reinforced, 280°F (138°C) HDT at 264 psi

(1.82 MPa); FDAcompliant, NSF Standard 61 listed (restrictions apply)

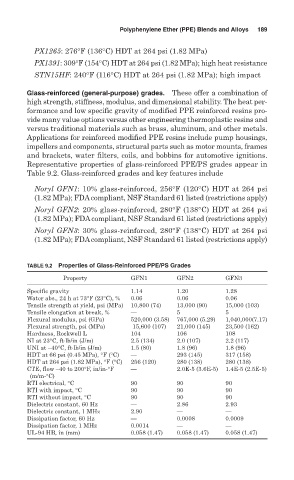

TABLE 9.2 Properties of Glass-Reinforced PPE/PS Grades

Property GFN1 GFN2 GFN3

Specific gravity 1.14 1.20 1.28

Water abs., 24 h at 73°F (23°C), % 0.06 0.06 0.06

Tensile strength at yield, psi (MPa) 10,800 (74) 13,000 (90) 15,000 (103)

Tensile elongation at break, % — 5 5

Flexural modulus, psi (GPa) 520,000 (3.58) 767,000 (5.29) 1,040,000(7.17)

Flexural strength, psi (MPa) 15,600 (107) 21,000 (145) 23,500 (162)

Hardness, Rockwell L 104 106 108

NI at 23°C, ft⋅lb/in (J/m) 2.5 (134) 2.0 (107) 2.2 (117)

UNI at −40°C, ft⋅lb/in (J/m) 1.5 (80) 1.8 (96) 1.8 (96)

HDT at 66 psi (0.45 MPa), °F (°C) — 293 (145) 317 (158)

HDT at 264 psi (1.82 MPa), °F (°C) 256 (120) 280 (138) 280 (138)

CTE, flow −40 to 200°F, in/in-°F — 2.0E-5 (3.6E-5) 1.4E-5 (2.5E-5)

(m/m-°C)

RTI electrical, °C 90 90 90

RTI with impact, °C 90 90 90

RTI without impact, °C 90 90 90

Dielectric constant, 60 Hz — 2.86 2.93

Dielectric constant, 1 MHz 2.90 — —

Dissipation factor, 60 Hz — 0.0008 0.0009

Dissipation factor, 1 MHz 0.0014 — —

UL-94 HB, in (mm) 0.058 (1.47) 0.058 (1.47) 0.058 (1.47)