Page 216 - Engineering Plastics Handbook

P. 216

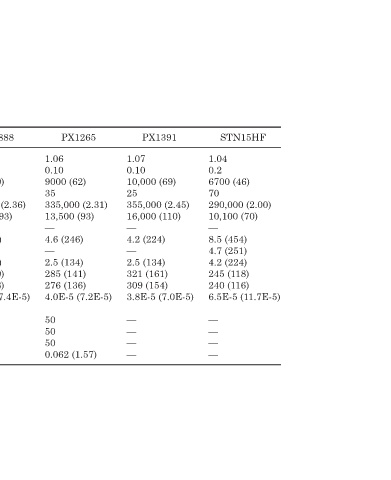

STN15HF 290,000 (2.00) 10,100 (70) 6.5E-5 (11.7E-5)

1.04 0.2 6700 (46) 70 — 8.5 (454) 4.7 (251) 4.2 (224) 245 (118) 240 (116) — — — —

PX1391 10,000 (69) 355,000 (2.45) 16,000 (110) 321 (161) 309 (154) 3.8E-5 (7.0E-5)

1.07 0.10 25 — 4.2 (224) — 2.5 (134) — — — —

PX1265 335,000 (2.31) 13,500 (93) 4.0E-5 (7.2E-5) 0.062 (1.57)

1.06 0.10 9000 (62) 35 — 4.6 (246) — 2.5 (134) 285 (141) 276 (136) 50 50 50

PX0888 342,000 (2.36) 13,500 (93) 4.1E-5 (7.4E-5)

1.04 0.10 8500 (59) 30 118 3.7 (198) — 2.5 (134) 265 (129) 262 (128) — — — —

Properties of General-Purpose PPE/PS Grades

PX0844 325,000 (2.24) 11,000 (76) 4.1E-5 (7.4E-5)

1.06 0.10 7200 (50) 42 114 4.4 (235) — 2.5 (134) 250 (121) 235 (113) — — — —

Property Water abs., 24 h at 73°F (23°C), % Tensile strength at yield, psi (MPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) NI at 73°F (23°C), ft⋅lb/in (J/m) NI at 0°F (−18°C), ft⋅lb/in (J/m) NI at −40°C/F, ft⋅lb/in (J/m) HDT at 66 psi (0.45 MPa

TABLE 9.1 Specific gravity Hardness, Rockwell R (m/m-°C) RTI electrical, °C RTI with impact, °C UL-94 HB, in (mm)

188