Page 251 - Engineering Plastics Handbook

P. 251

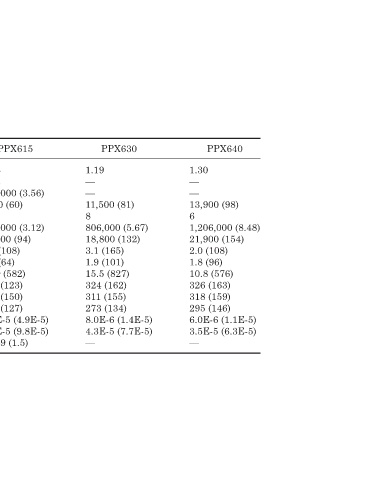

PPX640 13,900 (98) 1,206,000 (8.48) 21,900 (154) 10.8 (576) 6.0E-6 (1.1E-5) 3.5E-5 (6.3E-5)

1.30 — — 6 2.0 (108) 1.8 (96) 326 (163) 318 (159) 295 (146) —

PPX630 11,500 (81) 806,000 (5.67) 18,800 (132) 15.5 (827) 8.0E-6 (1.4E-5) 4.3E-5 (7.7E-5)

1.19 — — 8 3.1 (165) 1.9 (101) 324 (162) 311 (155) 273 (134) —

PPX615 506,000 (3.56) 444,000 (3.12) 13,300 (94) 10.9 (582) 2.7E-5 (4.9E-5) 5.4E-5 (9.8E-5) 0.059 (1.5)

1.08 0.03 8600 (60) 5 2.0 (108) 1.2 (64) 253 (123) 302 (150) 261 (127)

Properties of Glass-Reinforced PPE/PP Grades

Property Water abs., 24 h at 73°F (23°C), % Tensile strength at yield, psi (MPa) Tensile elongation at break, % NI at −22°F (−30°C), ft⋅lb/in (J/m) HDT at 66 psi (0.45 MPa), °F (°C) HDT at 264 psi (1.82 MPa), °F (°C) CTE, flow −40 to 100°F, in/in-°F (m/m-°C) CTE, crossflow −40 to 100°F,

TABLE 9.13 Specific gravity Tensile modulus, psi (MPa) Flexural modulus, psi (GPa) Flexural strength, psi (MPa) NI at 23°C, ft⋅lb/in (J/m) UNI at −40°C, ft⋅lb/in (J/m) Vicat B, °F (°C) UL-94 HB, in (mm)

213