Page 249 - Engineering Plastics Handbook

P. 249

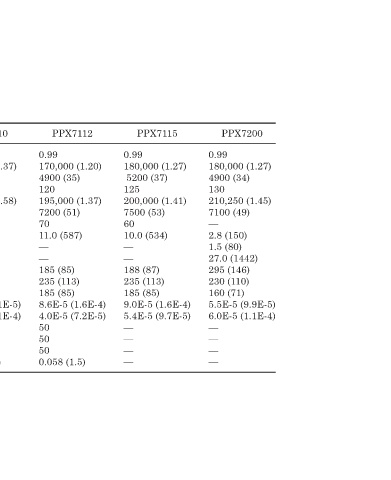

PPX7200 180,000 (1.27) 210,250 (1.45) 27.0 (1442) 5.5E-5 (9.9E-5) 6.0E-5 (1.1E-4)

0.99 4900 (34) 130 7100 (49) — 2.8 (150) 1.5 (80) 295 (146) 230 (110) 160 (71) — — — —

PPX7115 180,000 (1.27) 5200 (37) 200,000 (1.41) 10.0 (534) 9.0E-5 (1.6E-4) 5.4E-5 (9.7E-5)

0.99 125 7500 (53) 60 — — 188 (87) 235 (113) 185 (85) — — — —

PPX7112 170,000 (1.20) 195,000 (1.37) 11.0 (587) 8.6E-5 (1.6E-4) 4.0E-5 (7.2E-5) 0.058 (1.5)

0.99 4900 (35) 120 7200 (51) 70 — — 185 (85) 235 (113) 185 (85) 50 50 50

PPX7110 195,000 (1.37) 225,000 (1.58) 7500 (53) 4.5E-5 (8.1E-5) 6.2E-5 (1.1E-4) 0.058 (1.5)

0.97 5200 (37) 195 — 8.2 (443) 2.8 (149) — 282 (139) 236 (113) 171 (77) 50 50 50

Properties of PPE/PP Grades Property Tensile strength at yield, psi (MPa) NI at −22°F (−30°C), ft⋅lb/in (J/m) HDT at 66 psi (0.45 MPa), °F (°C) HDT at 264 psi (1.82 MPa), °F (°C) CTE, flow –40 to 100°F, in/in-°F (m/m-°C) CTE, crossflow –40 to 100°F, in/in-°F (m/m-°C)

TABLE 9.12 Specific gravity Tensile modulus, psi (GPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) Hardness, Rockwell R NI at 23°C, ft⋅lb/in (J/m) UNI at 23°C, ft⋅lb/in (J/m) Vicat B, °F (°C) RTI electrical, °C RTI with impact, °C RTI without impa

212