Page 244 - Engineering Plastics Handbook

P. 244

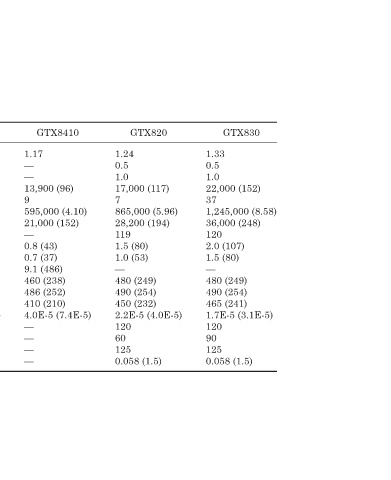

GTX830 22,000 (152) 1,245,000 (8.58) 36,000 (248) 1.7E-5 (3.1E-5) 0.058 (1.5)

1.33 0.5 1.0 37 120 2.0 (107) 1.5 (80) — 480 (249) 490 (254) 465 (241) 120 90 125

GTX820 17,000 (117) 865,000 (5.96) 28,200 (194) 2.2E-5 (4.0E-5) 0.058 (1.5)

1.24 0.5 1.0 7 119 1.5 (80) 1.0 (53) — 480 (249) 490 (254) 450 (232) 120 60 125

GTX8410 13,900 (96) 595,000 (4.10) 21,000 (152) 4.0E-5 (7.4E-5)

1.17 — — 9 — 0.8 (43) 0.7 (37) 9.1 (486) 460 (238) 486 (252) 410 (210) — — — —

Properties of Glass-Reinforced PPE/PA66 Grades

GTX810 13,000 (90) 575,000 (3.96) 22,500 (155) 2.8E-5 (5.04E-5) 0.058 (1.5)

1.16 0.5 1.0 10 119 1.5 (80) 1.0 (53) — 465 (241) 473 (245) 410 (210) 120 60 125

Property Water abs., 24 h at 73°F (23°C), % Water abs., equilib. 73°F (23°C), % Tensile strength at yield, psi (MPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) NI at −22°F (−30°C), ft⋅lb/in (J/m) HDT at 66 psi (0.45 MPa), °F (°C) HDT at 264 psi

TABLE 9.11 Specific gravity Hardness, Rockwell R NI at 23°C, ft⋅lb/in (J/m) UNI at 23°C, ft⋅lb/in (J/m) Vicat B, °F (°C) RTI electrical, °C RTI with impact, °C RTI without impact, °C UL-94 HB, in (mm)

208