Page 242 - Engineering Plastics Handbook

P. 242

Polyphenylene Ether (PPE) Blends and Alloys 207

Noryl GTX 902: 312°F (156°C) HDT at 66 psi (0.45 MPa); dimen-

sionally stable; paintable; gives Class A surface appearance

Noryl GTX 910: 380°F (193°C) HDT at 66 psi (0.45 MPa); dimen-

sionally stable grade useful in automotive online painted components;

gives Class A surface appearance

Noryl GTX 918W: 372°F (189°C) HDT at 66 psi (0.45 MPa); high flow

grade for under-the-hood and electrical applications requiring reten-

tion of properties under thermal load

Noryl GTX 964W: 365°F (185°C) HDT at 66 psi (0.45 MPa); high flow

grade useful for body panels, large parts, and thin-wall applications

Glass-reinforced PPE/PA grades. These offer increased stiffness, chem-

ical resistance, and dimensional stability. Compared with glass-rein-

forced polyamide 66 at equal glass levels, PPE/PA66 offers lower density

and higher strength and modulus under humid conditions and at ele-

vated temperatures. Comparative data appear in Table 9.10 [28].

Representative properties of glass-reinforced PPE/PA66 grades appear

in Table 9.11. Grades and key features include

Noryl GTX 810: 10% glass-reinforced; 473°F (245°C) HDT at 66 psi

(0.45 MPa); increased stiffness, high heat resistance, and high heat

resistance; suitable for automotive electrical connectors and lighting

applications

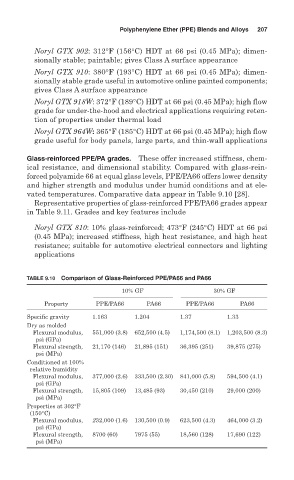

TABLE 9.10 Comparison of Glass-Reinforced PPE/PA66 and PA66

10% GF 30% GF

Property PPE/PA66 PA66 PPE/PA66 PA66

Specific gravity 1.163 1.204 1.37 1.33

Dry as molded

Flexural modulus, 551,000 (3.8) 652,500 (4.5) 1,174,500 (8.1) 1,203,500 (8.3)

psi (GPa)

Flexural strength, 21,170 (146) 21,895 (151) 36,395 (251) 39,875 (275)

psi (MPa)

Conditioned at 100%

relative humidity

Flexural modulus, 377,000 (2.6) 333,500 (2.30) 841,000 (5.8) 594,500 (4.1)

psi (GPa)

Flexural strength, 15,805 (109) 13,485 (93) 30,450 (210) 29,000 (200)

psi (MPa)

Properties at 302°F

(150°C)

Flexural modulus, 232,000 (1.6) 130,500 (0.9) 623,500 (4.3) 464,000 (3.2)

psi (GPa)

Flexural strength, 8700 (60) 7975 (55) 18,560 (128) 17,690 (122)

psi (MPa)