Page 241 - Engineering Plastics Handbook

P. 241

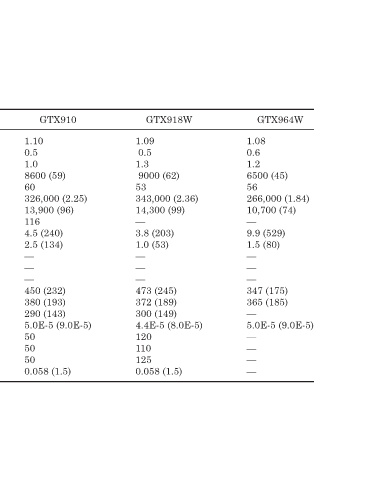

GTX964W 6500 (45) 266,000 (1.84) 10,700 (74) 347 (175) 365 (185) 5.0E-5 (9.0E-5)

1.08 0.6 1.2 56 — 9.9 (529) 1.5 (80) — — — — — — — —

GTX918W 9000 (62) 343,000 (2.36) 14,300 (99) 4.4E-5 (8.0E-5) 0.058 (1.5)

1.09 0.5 1.3 53 — 3.8 (203) 1.0 (53) — — — 473 (245) 372 (189) 300 (149) 120 110 125

GTX910 326,000 (2.25) 13,900 (96) 5.0E-5 (9.0E-5) 0.058 (1.5)

1.10 0.5 1.0 8600 (59) 60 116 4.5 (240) 2.5 (134) — — — 450 (232) 380 (193) 290 (143) 50 50 50

GTX902 325,000 (2.24) 13,000 (90) 5.0E-5 (9.05E-5) 0.058 (1.5)

1.08 0.4 1.0 8700 (60) 52 118 5.1 (272) 2.2 (117) 1.0 (53) 60 (3204) 60 (3204) 451 (233) 312 (156) 262 (128) 50 50 50

Properties of PPE/PA66 Grades Property Water abs., 24 h at 73°F (23°C), % Water abs., equilib. 73°F (23°C), % Tensile strength at yield, psi (MPa) NI at −22°F (−30°C), ft⋅lb/in (J/m) NI at −40°F (−40°C), ft⋅lb/in (J/m) UNI at −40°F (−40°C), ft⋅lb/in (J/m) HDT at 66 psi (0.45 MPa), °F (°C) HDT

TABLE 9.9 Specific gravity Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) Hardness, Rockwell R NI at 23°C, ft⋅lb/in (J/m) UNI at 23°C, ft⋅lb/in (J/m) Vicat B, °F (°C) RTI electrical, °C RTI with impact, °C RTI without impact, °C UL-94 HB, in (mm)

206