Page 328 - Engineering Plastics Handbook

P. 328

286 Engineering Plastics

175

25

500°F

260°C 150

Tensile strength, kpsi 20 420°F 125 MPa

470°F

243°C

216°C

15

300°F

149°C 100

Heat up Cool down 75

10

Cure cycle

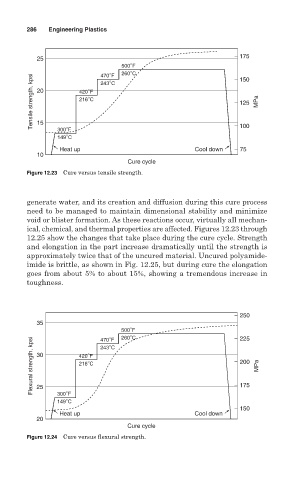

Figure 12.23 Cure versus tensile strength.

generate water, and its creation and diffusion during this cure process

need to be managed to maintain dimensional stability and minimize

void or blister formation. As these reactions occur, virtually all mechan-

ical, chemical, and thermal properties are affected. Figures 12.23 through

12.25 show the changes that take place during the cure cycle. Strength

and elongation in the part increase dramatically until the strength is

approximately twice that of the uncured material. Uncured polyamide-

imide is brittle, as shown in Fig. 12.25, but during cure the elongation

goes from about 5% to about 15%, showing a tremendous increase in

toughness.

250

35

500°F 225

260°C

Flexural strength, kpsi 30 420°F 200 MPa

470°F

243°C

216°C

25

300°F

149°C 175

150

Heat up Cool down

20

Cure cycle

Figure 12.24 Cure versus flexural strength.