Page 70 - Engineering Plastics Handbook

P. 70

44 Introduction

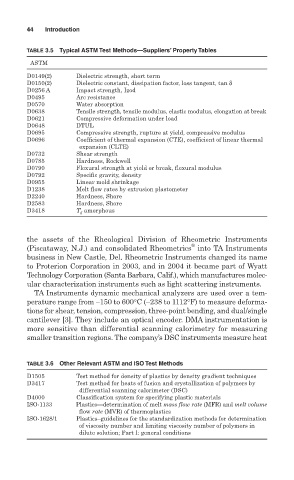

TABLE 3.5 Typical ASTM Test Methods—Suppliers’ Property Tables

ASTM

D0149(2) Dielectric strength, short term

D0150(2) Dielectric constant, dissipation factor, loss tangent, tan δ

D0256 A Impact strength, Izod

D0495 Arc resistance

D0570 Water absorption

D0638 Tensile strength, tensile modulus, elastic modulus, elongation at break

D0621 Compressive deformation under load

D0648 DTUL

D0695 Compressive strength, rupture at yield, compressive modulus

D0696 Coefficient of thermal expansion (CTE), coefficient of linear thermal

expansion (CLTE)

D0732 Shear strength

D0785 Hardness, Rockwell

D0790 Flexural strength at yield or break, flexural modulus

D0792 Specific gravity, density

D0955 Linear mold shrinkage

D1238 Melt flow rates by extrusion plastometer

D2240 Hardness, Shore

D2583 Hardness, Shore

D3418 T g amorphous

the assets of the Rheological Division of Rheometric Instruments

®

(Piscataway, N.J.) and consolidated Rheometrics into TA Instruments

business in New Castle, Del. Rheometric Instruments changed its name

to Proterion Corporation in 2003, and in 2004 it became part of Wyatt

Technology Corporation (Santa Barbara, Calif.), which manufactures molec-

ular characterization instruments such as light scattering instruments.

TA Instruments dynamic mechanical analyzers are used over a tem-

perature range from −150 to 600°C (−238 to 1112°F) to measure deforma-

tions for shear, tension, compression, three-point bending, and dual/single

cantilever [3]. They include an optical encoder. DMA instrumentation is

more sensitive than differential scanning calorimetry for measuring

smaller transition regions. The company’s DSC instruments measure heat

TABLE 3.6 Other Relevant ASTM and ISO Test Methods

D1505 Test method for density of plastics by density gradient techniques

D3417 Test method for heats of fusion and crystallization of polymers by

differential scanning calorimeter (DSC)

D4000 Classification system for specifying plastic materials

ISO-1133 Plastics—determination of melt mass flow rate (MFR) and melt volume

flow rate (MVR) of thermoplastics

ISO-1628/1 Plastics–guidelines for the standardization methods for determination

of viscosity number and limiting viscosity number of polymers in

dilute solution; Part I: general conditions