Page 223 - Estimators Piping Man Hour Manual

P. 223

206 Section Nine—INSULATION

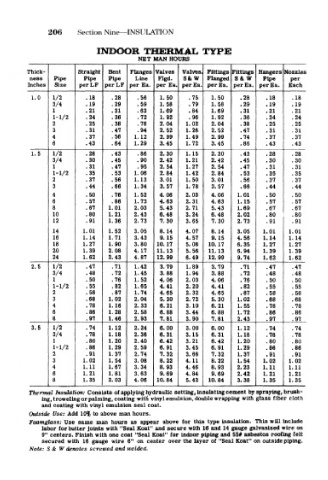

INDOOR THERMAL TYPE

NET MAN HOURS

Thick- Straight Bent Flanges Valves Valves, Fittings Fittings Hangers Nozzles

ness Pipe Pipe Pipe Line Flgd. S& W Flanged S& W Pipe per

Inches Size perLF perLF per Ea. per Ea. per Ea. perEa. perEa. perEa. Each

1.0 1/2 .18 .28 .56 1.50 .75 1.50 .28 .18 .18

3/4 .19 .29 .59 1.58 .79 1.58 .29 .19 .19

1 .21 .31 .63 1.69 .84 1.69 .31 .21 .21

1-1/2 .24 .36 .72 1.92 .96 1.92 .36 .24 .24

2 .25 .38 .76 2.04 1.02 2.04 .38 .25 .25

3 .31 .47 .94 2.52 1.26 2.52 .47 .31 .31

4 .37 .56 1.12 2.99 1.49 2.99 .74 .37 .37

6 .43 .64 1.29 3.45 1.72 3.45 .86 .43 .43

1.5 1/2 .28 .43 .86 2.30 1.15 2.30 .43 .28 .28

3/4 .30 .45 .90 2.42 1.21 2.42 .45 .30 .30

1 .31 .47 .95 2.54 1.27 2.54 .47 .31 .31

1-1/2 .35 .53 1.06 2.84 1.42 2.84 .53 .35 .35

2 .37 .56 1.13 3.01 1.50 3.01 .56 .37 .37

3 .44 .66 1.34 3.57 1.78 3.57 .66 .44 .44

4 .50 .76 1.52 4.06 2.03 4.06 1.01 .50 .50

6 .57 .86 1.73 4.63 2.31 4.63 1.15 .57 .57

8 .67 1.01 2.03 5.43 2.71 5.43 1.69 .67 .67

10 .80 1.21 2.43 6.48 3.24 6.48 2.02 .80 .80

12 .91 1.36 2.73 7.30 3.65 7.30 2.73 ,91 .91

14 1.01 1.52 3.05 8.14 4.07 8.14 3.05 1.01 1.01

18 1.14 1.71 3.43 9.15 4.57 9.15 4.56 1.14 1.14

18 1.27 1.90 3.80 10.17 5.08 10.17 6.35 1.27 1.27

20 1.39 2.08 4.17 11.13 5.56 11.13 6.94 1.39 1.39

24 1.62 2.43 4.87 12.99 6.49 12.99 9.74 1.62 1.62

2.5 1/2 .47 .71 1.42 3.79 1.89 3.79 .71 .47 .47

3/4 .48 .72 1.45 3.88 1.94 3.88 .72 .48 .48

1 .50 .76 1.52 4.06 2.03 4.06 .76 .50 .50

1-1/2 .55 .82 1.65 4.41 2.20 4.41 .82 .55 .55

2 .58 .87 1.74 4.65 2.32 4.65 .87 .58 .58

3 .68 1.02 2.04 5.30 2.72 5.30 1.02 .68 .68

4 .78 1.16 2.33 6.21 3.10 6.21 1.55 .78 .78

6 .86 1.28 2.58 6.88 3.44 6.88 1.72 .86 .86

8 .97 1.46 2.93 7.81 3.90 7.81 U 2.43 .97 .97

3.5 1/2 .74 1.12 2.24 6.00 3.00 6.00 1.12 .74 .74

3/4 .78 1.18 2.36 6.31 3.15 6.31 1.18 .78 .78

1 .80 1.20 2.40 6.42 3.21 6.42 1.20 .80 .80

1-1/2 .86 1.29 2.59 6.91 3.45 6.91 1.29 .86 .86

2 .91 1.37 2.74 7.32 3.66 7.32 1.37 .91 .91

3 1.02 1.54 3.08 8.22 4.11 8.22 1.54 1.02 1.02

4 1.11 1.67 3.34 8.93 4.46 8.93 2.23 1.11 1.11

6 1.21 1.81 3.63 9.69 4.84 9.69 2.42 1.21 1.21

8 1.35 2.03 4.06 10.84 5.42 10.84 3.38 1.35 1.35

Thermal Insulation: Consists of applying hydraulic setting, insulating cement by spraying, brush-

ing, troweling or palming, coating with vinyl emulsion, double wrapping with glass fiber cloth

and coating with vinyl emulsion seal coat.

Outside Use: Add 10% to above man hours.

Foamgtoss: Use same man hours as appear above for this type insulation. This will include

labor for butter joints with "Seal Koat" and secure with 16 and 14 gauge galvanized wire on

9" centers. Finish with one coat "Seal Koat" for indoor piping and 55# asbestos roofing felt

secured with 16 gauge wire 6" on center over the layer of "Seal Koat" on outside piping.

Note: S & W denotes screwed and welded.