Page 71 - Estimators Piping Man Hour Manual

P. 71

54 Section One-SHOP FABRICATION

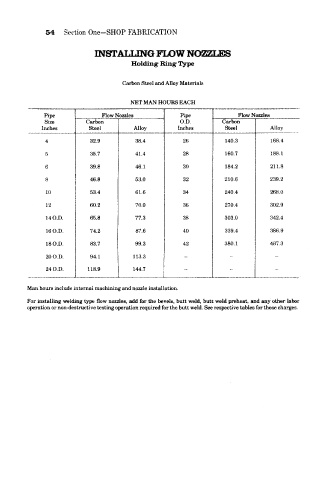

INSTALLING FLOW NOZZLES

Holding Ring Type

Carbon Steel and Alloy Materials

NET MAN HOURS EACH

Pipe Flow Nozzles Pipe Flow Nozzles

Size Carbon O.D. Carbon

Inches Steel Alloy Inches Steel Alloy

4 32.9 38.4 26 140.3 168.4

5 35.7 41.4 28 160.7 188.1

6 39.8 46,1 30 184.2 211.8

8 46.8 53.0 32 210.6 239.2

10 53.4 61.6 34 240.4 268.0

12 60.2 70.0 36 270.4 302.9

14 O.D. 65.8 77.3 38 303.0 342.4

16O.D. 74.2 87.6 40 339.4 386.9

18 O.D. 83.7 99.3 42 380.1 467.3

20 O.D. 94.1 113.3 -- „ ..

24O.D. 118.9 144.7 ..

Man hours include internal machining and nozzle installation.

For installing welding type flow nozzles, add for the bevels, butt weld, butt weld preheat, and any other labor

operation or non-destructive testing operation required for the butt weld. See respective tables for these charges.